Phil O

Western Thunderer

View attachment 182486

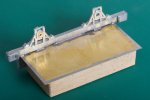

I have had a bit of a culture shock going from brass to whitemetal - assembly of the boiler has been spread over four days of sessions with solder, glue, filler and more glue. The sides of the firebox are the perfect shape to fit the backhead but they stop most of 3 mm apart.

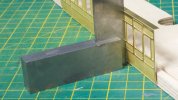

I put the model above my eye level for the glue to cure . . . the fitting on the top of the firebox ended up twisted so I filed off the nut and stud detail, I would rather have no detail than wrong detail. I will try to remember to blend this into the firebox the next time I mix up some Milliput.

View attachment 182487

The steam outlet could go onto either ring of the boiler, I chose the forward one to try for a slightly more Victorian look.

I suspect this model will look a whole lot better with a coat of paint to bring the various surfaces together. This could be months away so I have plenty of time to find out whether the Lomac is a suitable wagon to carry it and how the chains should go.

Hi Richard,

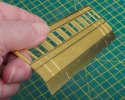

The front tube plate of the boiler on the well wagon is somewhat strange, to my professional eye, boilermaker rtd.

The tubes should end two or three rows lower, otherwise the firebox crown plate will be up against the wrapper. The firebox crown plate is usually around 6 inches above the top row of tubes, the tubes only tend to be about half way up the barrel.

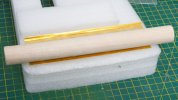

. It's a bit late to get the torch out so I put a narrow bead of the epoxy along the inside of the gap. I used masking tape to keep this tidy.

. It's a bit late to get the torch out so I put a narrow bead of the epoxy along the inside of the gap. I used masking tape to keep this tidy.