Richard Gawler

Western Thunderer

The extra dowels arrived yesterday and I have finished building the baseboards.

The fun stopped for a while because the all of the alignment holes in the ends of the traverser module turned out to be set lower than those on the all of the other baseboards. The effect would be to raise the whole traverser module. I asked the manufacturer about this and it turns out my bargain second hand traverser (bought from a third party) is a special made for someone who wanted a higher deck to compensate for underlay elsewhere

Well, it wouldn't be much of a hobby if it everything was easy. Most every idea to sort things out would turn the layout from being a modular one into a sectional one, so I ended up moving the holes . . .

The traverser arrived with the 25 mm dowels fitted flush into the frame. These came out with a Forstner bit, some more cleanly than others.

Then I opened up these holes using a sort of side-and end-cutting milling cutter in the Minicraft drill, added the 3 mm spacers and plugged all of the too-low 6 mm holes.

The pattern makers dowels and their sockets are fitted with rather a lot of epoxy glue and their usual screws.

For the two sockets, I put cling film over the two dowels on module (A), this kept the surplus glue at bay and let me separate the joint afterwards

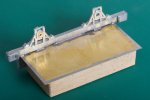

This is the completed fiddle yard in its "maximum" configuration.

Every instruction followed.

So I now have my four baseboard modules. Every module connects to every other module, with the exception that nothing connects to the far end of the diorama because I have no need to do this.

I need to build some kind of sub-frame to hold the modules, this needs to adaptable enough to hold the modules chosen for the day, be presentable enough for use at home and fit into the back of a Yaris. Another day.

The fun stopped for a while because the all of the alignment holes in the ends of the traverser module turned out to be set lower than those on the all of the other baseboards. The effect would be to raise the whole traverser module. I asked the manufacturer about this and it turns out my bargain second hand traverser (bought from a third party) is a special made for someone who wanted a higher deck to compensate for underlay elsewhere

Well, it wouldn't be much of a hobby if it everything was easy. Most every idea to sort things out would turn the layout from being a modular one into a sectional one, so I ended up moving the holes . . .

The traverser arrived with the 25 mm dowels fitted flush into the frame. These came out with a Forstner bit, some more cleanly than others.

Then I opened up these holes using a sort of side-and end-cutting milling cutter in the Minicraft drill, added the 3 mm spacers and plugged all of the too-low 6 mm holes.

The pattern makers dowels and their sockets are fitted with rather a lot of epoxy glue and their usual screws.

For the two sockets, I put cling film over the two dowels on module (A), this kept the surplus glue at bay and let me separate the joint afterwards

This is the completed fiddle yard in its "maximum" configuration.

Every instruction followed.

So I now have my four baseboard modules. Every module connects to every other module, with the exception that nothing connects to the far end of the diorama because I have no need to do this.

I need to build some kind of sub-frame to hold the modules, this needs to adaptable enough to hold the modules chosen for the day, be presentable enough for use at home and fit into the back of a Yaris. Another day.

Last edited: