Richard Gawler

Western Thunderer

The (fictional) Heybridge Railway had some kind of a passenger service, and for a while this was a public service. This was a pretty minimal provision - probably one brake third vehicle on a four-wheeled underframe. The service began at or soon after the inception of the line and the station was named 'Heybridge'. By 1907, most users had given up because it was easier to take the Witham train to Maldon East and walk the mile to Heybridge instead of walking from Langford (GER) to Langford Junction (HLLR). The GER breathed a sigh of relief and renamed Maldon East as 'Maldon and Heybridge’. The HLLR continued to provide an internal passenger service on a 'runs when required' basis; this was found useful for barge operators and employees of the canal company.

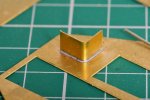

This is the kit for an 0 Gauge Station Shelter by Laser Cut Model Railways. I built this earlier this year, before I did my first metal wagon kit. The building went together really easily. It is a mixture of 2 mm MDF and 1 mm card.

I added a strip of obechi across the front to hold it straight and make sure I don't push my thumb through the front of the model.

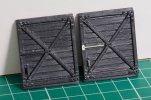

I get better colour with my new camera. I brush painted the model with Tamiya acrylics (not the Vallejo in the second photo). I tried to give it a fairly dowdy look.

The primer was Rustins MDF Sealer followed by Halfords grey primer. I stopped painting the top coats on the rear wall before I got complete coverage to try to help the weatheirng when I come to it. The roof is sandpaper with pencil lines to represent the joins. I tried adding separate strips of sandpaper but they looked like a school project.

This was a particularly pleasant kit to build. I think it would work well in many settings, just change the colour palette to suit. I will add guttering and a down pipe if they are going to be visible on the layout, I can be quite lazy with this sort of thing.

This is the kit for an 0 Gauge Station Shelter by Laser Cut Model Railways. I built this earlier this year, before I did my first metal wagon kit. The building went together really easily. It is a mixture of 2 mm MDF and 1 mm card.

I added a strip of obechi across the front to hold it straight and make sure I don't push my thumb through the front of the model.

I get better colour with my new camera. I brush painted the model with Tamiya acrylics (not the Vallejo in the second photo). I tried to give it a fairly dowdy look.

The primer was Rustins MDF Sealer followed by Halfords grey primer. I stopped painting the top coats on the rear wall before I got complete coverage to try to help the weatheirng when I come to it. The roof is sandpaper with pencil lines to represent the joins. I tried adding separate strips of sandpaper but they looked like a school project.

This was a particularly pleasant kit to build. I think it would work well in many settings, just change the colour palette to suit. I will add guttering and a down pipe if they are going to be visible on the layout, I can be quite lazy with this sort of thing.

Last edited: