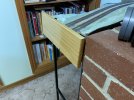

A rear view showing the Brass bracket in position and the Brass screw which is the Adjustable rear bearing along with its locknut.

Showing the main shaft in position.

In this photo there is a Armature still to be attached to the main shaft, the weight of this armature plus the weight of the Needle which isn't much will make them both hang downwards "by gravity" this is the Fail Safe position and the Needle will point Downwards to the word WRONG on the face of the Instrument.

I will jump the process a little bit so I can explain about the relays as these became the source of the Armatures.

Originally I was going to build a small Galvanometer to operate each Instrument similar to Spagnoletti's design but I soon dismissed this idea as the cost of the copper enamel wire had a ridiculous price tag. After having a good think about how I could make these work I figured I could operate these Instruments by individual coils which would make the Instrument work exactly as the prototype dose but by a different method.

As individual coils cannot be bought off the shelf I realised Relays would be a source of supply that had coils with the correct resistance and good Magnetic pull so I started experimenting with old relays of various types I had.

I attached a Thermocouple to each coil and monitored its Temperature at different voltages, I then pulled the Armature off each relay and checked this again on average the temperature rose up by about 10C some worse than others while I did this I also took note of how much Magnetic pull each coil could give at a particular voltage, at the end the Relays that I have been using for the Turntable and Lift Up Section proved to be the best for what I required.

The end result when these Instruments were finished was good the Pick up voltage is around 6 volts DC but is sluggish at 8 volts they move quickly the coil running temperature is around 39C at 8 volts and 47C at 10 volts so I had a win.

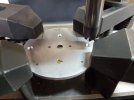

This is the type of Relay that I used.

The first thing I did was to remove the Armature with its contact piece.

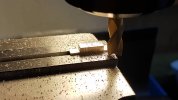

Next I cut off the lower contact section.

The section with the coil terminals that remained attached was tidied up with a file.

The left hand section of the piece that is being cut off in the photo is to become a Armature for one of the Main shafts.

The metal on this relay is of Soft Iron so it doesn't become magnetised when held against a electro magnet for any length of time.

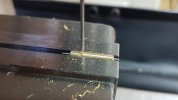

The ruff sawn metal remaining on the coil including the spring mount was filed down level with the plastic bobbin

The reason for this is this side of the plastic bobbin rests against the rear of the Aluminium Face plate and in doing

this the coil only requires one mounting screw to hold it in place.