David Waite

Western Thunderer

Hello I’m David Waite

First of all as the title says the layout is called CHIMTONSTOKE, as I explained to the group in my introduction as a new member

I built the house myself and naturally as a railway enthusiast I wanted a Train Room so I structurally designed the house to support an Attic. The Attic room measures 30’x 12’ there is a chimney and a staircase in the room that the layout had to get past and Four windows that need unhindered access and of course there’s the walking areas to access the various sections of the layout.

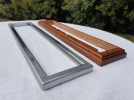

I’ve attached a floor plan I drew today outlining the Attic & layout which should explain what the layout is about better than I could explain in words, the plan is not to scale and is far from accurate but it shows the basic track configuration. As can be seen CHIMTONSTOKE is a Terminus station with a double track mainline that splits at PINE OAK JUNCTION via the double track junction, the Main Line heads towards COALCHESTER and the Main Branch to BRIDGETON both these destinations are return loops and will each have 4 storage sidings on them, the BRIDGETON loop will be on a higher level and directly above the COALCHESTER loop and these will be in the storage room outside the end of the Attic room. The track is built to OO gauge but with tight tolerances using FB / NS code 70 rail on copper clad sleepers so far I’ve built about 20‘ of double track main line and some of the WAITECOTT branch. There are 3 lift up sections, one small manual lift up section near the chimney and a double lift up section on the down side of PINE OAK JUNCTION, this double lift up section has a manual side which is lowered down first then the other half is lowered and raised by a 12 VDC geared motor which gets its power supply from a SLA battery that is charged by a solar panel out on the roof of the house the reason it is battery powered is because we often have power outages and the reason I made the section electrically driven is because my shoulders are not good so the motor lifts it for me and why is it a double lift up section that’s because I have a TV under the window and when both sections are up I can watch my Television . There is no scenery and basically empty base boards but intend to change that situation next year.

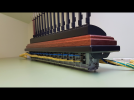

The Layout will be worked by 6 hand built SINGLE WIRE TWO POSITION DOUBLE LINE BLOCK INSTRUMENTS all of which were installed in 1996 and are in full working order. PINE OAK JUNCTION has a 30 Lever All Steel Lever Frame and will be fully mechanically interlocked, signals that are out of sight from the Box or signals that won’t exist due to scale distances will be repeated by Signal Arm Repeater Instruments, 6 have been made and 3 are still in production only their timber casings need to be made, I will show photos and give details of all the items I’ve made so far when I learn how to operate my new computer over the coming weeks this is where my daughter put all my photos.

First of all as the title says the layout is called CHIMTONSTOKE, as I explained to the group in my introduction as a new member

I built the house myself and naturally as a railway enthusiast I wanted a Train Room so I structurally designed the house to support an Attic. The Attic room measures 30’x 12’ there is a chimney and a staircase in the room that the layout had to get past and Four windows that need unhindered access and of course there’s the walking areas to access the various sections of the layout.

I’ve attached a floor plan I drew today outlining the Attic & layout which should explain what the layout is about better than I could explain in words, the plan is not to scale and is far from accurate but it shows the basic track configuration. As can be seen CHIMTONSTOKE is a Terminus station with a double track mainline that splits at PINE OAK JUNCTION via the double track junction, the Main Line heads towards COALCHESTER and the Main Branch to BRIDGETON both these destinations are return loops and will each have 4 storage sidings on them, the BRIDGETON loop will be on a higher level and directly above the COALCHESTER loop and these will be in the storage room outside the end of the Attic room. The track is built to OO gauge but with tight tolerances using FB / NS code 70 rail on copper clad sleepers so far I’ve built about 20‘ of double track main line and some of the WAITECOTT branch. There are 3 lift up sections, one small manual lift up section near the chimney and a double lift up section on the down side of PINE OAK JUNCTION, this double lift up section has a manual side which is lowered down first then the other half is lowered and raised by a 12 VDC geared motor which gets its power supply from a SLA battery that is charged by a solar panel out on the roof of the house the reason it is battery powered is because we often have power outages and the reason I made the section electrically driven is because my shoulders are not good so the motor lifts it for me and why is it a double lift up section that’s because I have a TV under the window and when both sections are up I can watch my Television . There is no scenery and basically empty base boards but intend to change that situation next year.

The Layout will be worked by 6 hand built SINGLE WIRE TWO POSITION DOUBLE LINE BLOCK INSTRUMENTS all of which were installed in 1996 and are in full working order. PINE OAK JUNCTION has a 30 Lever All Steel Lever Frame and will be fully mechanically interlocked, signals that are out of sight from the Box or signals that won’t exist due to scale distances will be repeated by Signal Arm Repeater Instruments, 6 have been made and 3 are still in production only their timber casings need to be made, I will show photos and give details of all the items I’ve made so far when I learn how to operate my new computer over the coming weeks this is where my daughter put all my photos.