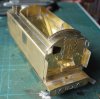

A Crewe of tenders? I've had my head down getting these together, I had the hopper crooked in one and I thought I might get away with it, but eventually it comes back to bite you as it means that other components will not fit, and after far too much contemplation, I ended up cutting out the solder along the back and one side, bashing it out and redoing it - fortunately without any damage to the side sheet. A salutary lesson to double check that things are square, how many times have I told myself that? Some of the white metal items are soldered, others fixed with Epoxy, I can never quite make my mind up which is best. I added a mounting plate for the water treatment hatch, I'm not sure if they all had it, but at least one of Annesley's fleet had the patch. I soldered as much from the inside as I could before adding the chassis. I love the 1F tenders, they just look huge. Other items, I added the 2 pipe oilers at the front outside of the frames, stays for the front steps and remembered that the sieve boxes are not hard up against the frames, despite there being a convenient spigot on the back of the casting. The axle box and spring castings lack detail on the spring hangers. I'll live with that for the moment.

One thing I could not live with, was the wire brake stretchers and white metal brakes in the kit, so I used Ragstone lost wax castings which are actually designed to prototypically hang off the inside of the our frames. I had to make mounting pads from scrap etch to mount them on the inner frames and drilled the ends of the stretchers to take 1mm brass rod. drilled out, 14Ba nuts were then added on the ends. The frame stretchers are 'U' shaped in reality, so strip from scrap etches ( again ) were soldered to the sides of the flat etch in the kit. The rear one is trapped by scoop lifter and to enable the chassis to separate from the main body, the stretchers screw with 14BA screws to 2mm 'L' angle soldered to the insides of the frames in the appropriate locations. I also had to knock up 12 small cranks to join the brake shaft to the pull rods, now that was tedious. Just pick ups to add now. The centre bearing has a 1mm brass rod soldered into a drilling which locates into a split pin handrail knob on the inside of the frame. This allow is to float in the slot without the bearing rotating.