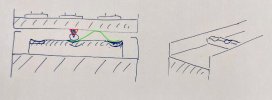

I now have an inconsequential-looking length of track to align the tracks on every other module.

In summary:

- A fresh piece of Chartwell’s finest (imperial graduations)

- Two lengths of double-sided adhesive tape

- PVA glue dabbed under the sleepers in between the lengths of tape

- Code 100 Hi-Ni rail from Kalgarin Models

- Plywood sleepers from C&L Finescale

- Spikes from Rexel no.56 staples, blackened and separated using heat

The rail is soldered onto brass screws near each end. The staples are pulled tight over a scrap of 0.8 mm wire and trimmed flush to make the spike heads.

I am pre-drilling holes for the spikes. This lets me hold a spike with pliers, insert the head past the rail head (this is rather broader than on the usual 00/H0 code 100) and rotate the spike to rest its head very near or just touching the web of the rail. The holes are large enough to take a dab of CA glue placed on the bottom of the spike and taken with it into the hole. This all seems to have set solid overnight.

The rail has a slight lateral curve in its natural state, so arranging it to curve inwards lets the second rail rest naturally against the track gauge.

I have closed up the gap mentioned in earlier posts. It remains for the camera, and if I hold the model up to the light. If the overall effect is what really counts, then this is down in the noise floor.

I remembered to put the dropper wires on before laying the rails

The pairs of spikes

photographed at the Mendlesham seem to be rather sparse so I have missed these out for this short length. I will try to remember them when I try to represent the rail joints on the diorama.

These tiny spikes are going to transmit all of the running noise into the baseboard structure. The cork is now only here to provide a flat surface and a better appearance on the areas without scenics.

Regarding expansion, I have built this at an ambient temperature of about 17 degrees C. This is roughly half-way between the extremes of a car boot in winter and the house in a hot summer. Fairly obviously, the only way the rails can move is upwards but I am optimistic these are short enough to stay put.

I can try modifying a small screwdriver to hold the spikes but at the moment I have coped using the small pliers. I have managed about two minutes per spike, so perhaps 90 minutes to build this after preparing all of the parts. So I can expect about three hours per yard, just about fast enough to stay below my boredom threshold.

- could the dropper wires have been soldered to the rail where it was going to sit on top of a sleeper and a groove taken out of the sleeper so it sat down? That way you would maintain the light railway effect with 'daylight' between the rail and ballast as seen in the Mendlesham photo, and wouldn't have to ballast to the top of the sleeper to hide the wires.

- could the dropper wires have been soldered to the rail where it was going to sit on top of a sleeper and a groove taken out of the sleeper so it sat down? That way you would maintain the light railway effect with 'daylight' between the rail and ballast as seen in the Mendlesham photo, and wouldn't have to ballast to the top of the sleeper to hide the wires.

.

.