That's exactly my intention, I have both crane and loco kit's to hand, I just need time...

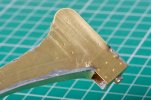

My completed crane jib.

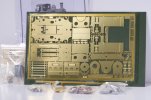

This is my fourth brass kit, the first three were wagons. The jib is not terribly difficult to assemble, the hardest part for me was working out how to hold the parts togehter for soldering. I am tempted to buy a leather glove for the holding hand.

I did find the instructions to be a bit challenging so if forewarned is forearmed . . .

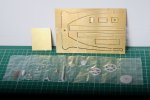

The jib has two sides and four covers: underside, top, rear and front. The covers go on in this sequence, so the front/back alignment of the underside dictates everything that follows. The instructions for the underside:

"This part should be fitted . . . starting level with the vertical front edge of the jib"

1. I began by forming a radius on the broader end of the underside so it would sit snugly against the front of the side frames, and soldered this part into place. So I used up about 3 mm of the length of the underside going around a curve to reach onto the vertical edges. The instructions don't mention a radius, but it worked.

2. I added the top cover, the narrow end of the top cover aligns with the narrow end of the underside.

3. I added the rear cover, beginning at the bottom and working upwards and then over the curve at the top. I ended up finding the rear cover was about half a millimetre too long, so it was easy to trim the broad end of the top cover and everything fitted perfectly. Beginners luck I am sure.

The front cover has to be formed into a semi-circular shape. I think life would be easier if this cover was a millimetre longer and I contemplated making a new part. I anealed the front cover to let me form the curve and life would have been easier still if I had done this before starting to form the shape and not part way though when I realised it was too tough to get into the proper shape. My attempt at a semi-circle is a bit rough but no-one will look at it from underneath.

My biggest failing on the jib was to solder it up with a cross-section like a parallelogram and not a rectangle. I noticed this too late to put it right. It is the sort of job I know I would do better next time . . . I have a feeling it won't show up unless I put a try square agianst the side of the jib on the finished model.

I took most of four hours to put the jib together! I am sure Rob will do it in less.