I would generally concur that sound in locomotives can enhance a model and as alluded to by the previous correspondents

@Oban27 @oldravendale @LarryG @simond and

@Suffolk Dave there are a number of gimmicky sounds which are a waste of time.

In my steam, diesel and electric locos - both O and HO scale - I spend alot of time tinkering with the sound levels in the CVs to 'tune' them to my satisfaction.

My

bête noire in steam locomotives is the the primary drive sound or exhaust beats as they do not sound right with them all being at the same volume. Rather than buy a sound profile for any given locomotive, and having an ESU Lokprogrammer, I download the closest sound from the ESU sound file bank and create my own as being free they are not locked.

With the downloaded sound files being unlocked I then dive into the individual sounds and alter the volumes. As I mentioned above it is the drive sound which requires the most attention and I alter the 2 cylinder CHUFF, CHUFF, CHUFF, CHUFF volumes to create them as I hear them to

CHUFF, CHUFF,

CHUFF,

CHUFF - with the emphasis on the first beat as this appears the loudest. Unfortunately many steam sound profiles keep these at the same volume and it is only when the speed increases the volumes become similar.

In addition, depending on the loco I may also include a 'rod clank' which can be heard when the loco is drifting and/or slowing down at which point the chuf, chuff sound cuts out - only to reappear when accelerating.

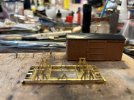

Also the speaker installation can play a significant role and in the larger scales I make it a point of being able to fit the largest possible and design this into the build rather the retro-fit when building kits. In my dealings with sound I have also noticed quite a number of speakers have a limited frequency range and I have spent time checking these to find out whether they can drop down to the lower Hz levels to improve the bass and get away from the tinny sound.

Again, as noted by prevoius correspondents diesels and electrics are easier but you still have to pay attention to the volume levels of certain sounds and the diesel type - mechanical, electric, hydraulic and with electric traction AC or DC.

At the end of the day I end up with what I want and all is fine.

And finally, overall sound volume - I have this programmed as a function so I can turn it down to barely audible at home where background noises are lower and increase at exhibitions so it can just be heard at 1m distance.

And apologies for the long diversion.