Richard Gawler

Western Thunderer

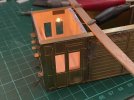

Apart from deliberately using solder as a filler, I am trying to use the GER van to get my soldering under more control and up to a better standard. I now have a few techniques for soldering parts together, and I am getting better at choosing the right way for the parts to hand. I am also trying to do the soldering without leaving myself quite so much tidying up to do.

If I had done these horizontal strips below the roof a year ago I would have probably tried to solder them throughout their lengths. Now they are tacked in the three places where they touch, much neater and far less solder.

I am assembling all of the brass parts using 188 degree solder, this usually worked with a 40 watt iron and sometimes tidied up with my microflame torch. The iron is an ex-Weller design marketed by CK and bought from Screwfix. I bought a conical bit for it and I use this bit for all of my work on brass. I get on with this bit, the shape makes it easy to get two points of contact in internal corners and the smallish size near the tip doesn't trail huge amounts of unwanted tinning around the work. The torch is useful because it doesn't physically touch the parts. I still overheat things in places, and this brings a reddish residue of copper to the surface. The glass fibre pencil is very good at restoring the colour to make the photos look better, though experience tells me the primer doesn't mind the colour of the brass.

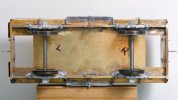

I have given the model a floor from 0.3 mm brass to hold the model square. This is also sturdy enough to let me twist the two long sides relative to each other and persuade them to line up with each other and stay put. I haven't decided how to fix the roof but I would like it to be detachable, this would make painting and any repairs easier.

If I had done these horizontal strips below the roof a year ago I would have probably tried to solder them throughout their lengths. Now they are tacked in the three places where they touch, much neater and far less solder.

I am assembling all of the brass parts using 188 degree solder, this usually worked with a 40 watt iron and sometimes tidied up with my microflame torch. The iron is an ex-Weller design marketed by CK and bought from Screwfix. I bought a conical bit for it and I use this bit for all of my work on brass. I get on with this bit, the shape makes it easy to get two points of contact in internal corners and the smallish size near the tip doesn't trail huge amounts of unwanted tinning around the work. The torch is useful because it doesn't physically touch the parts. I still overheat things in places, and this brings a reddish residue of copper to the surface. The glass fibre pencil is very good at restoring the colour to make the photos look better, though experience tells me the primer doesn't mind the colour of the brass.

I have given the model a floor from 0.3 mm brass to hold the model square. This is also sturdy enough to let me twist the two long sides relative to each other and persuade them to line up with each other and stay put. I haven't decided how to fix the roof but I would like it to be detachable, this would make painting and any repairs easier.

Last edited: