PhilH

Western Thunderer

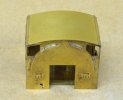

Wagons for use with the end tippler require opening end doors of course. The Peco 16T mineral wagon kits already provide for these and just require the removal of the lugs on the inside which normally keep the door closed by friction.

They then require some form of operating door catch to keep the door closed. I did have some reservations about the plastic door hinges but so far they seem to be standing up to the regular opening and closing.

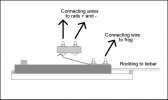

The door catches comprise a short length of nickel silver wire passing through a hole drilled in the buffer beam with the ends bent upwards to form the catch. On the inner end is silver soldered a crank or lever connected to an operating wire with a hooked end just below the solebar.

It can thus be operated by the shunter's pole without touching the wagon, although its necessary to make sure the door is fully closed before returning the catch to its vertical position.

The wagons are painted in the dark blue livery used for steel internal user wagons on the NCB's Walkden Railway System.

They then require some form of operating door catch to keep the door closed. I did have some reservations about the plastic door hinges but so far they seem to be standing up to the regular opening and closing.

The door catches comprise a short length of nickel silver wire passing through a hole drilled in the buffer beam with the ends bent upwards to form the catch. On the inner end is silver soldered a crank or lever connected to an operating wire with a hooked end just below the solebar.

It can thus be operated by the shunter's pole without touching the wagon, although its necessary to make sure the door is fully closed before returning the catch to its vertical position.

The wagons are painted in the dark blue livery used for steel internal user wagons on the NCB's Walkden Railway System.

.

.