S

Simon Dunkley

Guest

Good work - looks promising! (And cheap!)Pugsley said:The first motor assembly is nearly finished, just the wheel/axle/final drive gear part to sort out now. Here it is, loosely bodged together, to give an idea of how it's going to work:

The back to backs have been set to the correct measurement (ish) in the pic, which shows that there's not a lot of room down there!

The threaded axles haven't really worked as planned, so plan B is to have full length continuous axles.

Something like the GW models wheel press for 4mm scale would do fine - in fact, if you have access to one, it may be all that you need.I'm currently thinking about how I'm going to press the wheels onto the axles, but will probably cobble something together that uses the lathe or mill to provide the necessary force.

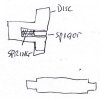

Failing that, a couple of discs on stubs (side profile of a T shape, if you get my drift. However, you may need to be able to locate the wheel centres accurately, so will need a couple of short stub axles a thou or so less than the real axle diameter. These really need to be spring loaded, with a spigot passing down the centre of the spring, so that there is a positive stop when the axle is pressed home fully.

The alternative - and it may be too late for this - is to have the wheel bores less than the axle diameter, with the ends of the axles turned down to fit, and the centre section used to set the back-to-back.

The extremely crude sketch appended hopefully makes this clearer, or at least less obscured.

I've had a look at your etch and your description and I thought I should perhaps drop in this enquiry now, just in case there is an error in the geometry you're employing - the holes in the bogie sides equally spaced between the wheels rang alarm bells...

I've had a look at your etch and your description and I thought I should perhaps drop in this enquiry now, just in case there is an error in the geometry you're employing - the holes in the bogie sides equally spaced between the wheels rang alarm bells...  :scratch:

:scratch:

), but might do something simple next - I have a PRMRP VDA van to build, although I will have to modify it slightly to spring it, it's nowhere near as big a job as the TTA, or the 37! I will be going back to 4mm scale for a bit before that though, I've still got a 455 and a layout to finish!

), but might do something simple next - I have a PRMRP VDA van to build, although I will have to modify it slightly to spring it, it's nowhere near as big a job as the TTA, or the 37! I will be going back to 4mm scale for a bit before that though, I've still got a 455 and a layout to finish!