You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

P A D

Western Thunderer

Hi Mick,

I had to cut the foil at the corners about half way from the front edge, then fold and solder. A bit of filing and fettling and it looks the part, or will do after painting. The brass bellows was working, but even after compression during handling and cleaning up, it showed sings of cracking on one of the folds. It will be fine now it's fixed and once it's painted, wont show.

Cheers,

Peter

I had to cut the foil at the corners about half way from the front edge, then fold and solder. A bit of filing and fettling and it looks the part, or will do after painting. The brass bellows was working, but even after compression during handling and cleaning up, it showed sings of cracking on one of the folds. It will be fine now it's fixed and once it's painted, wont show.

Cheers,

Peter

P A D

Western Thunderer

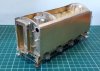

So having added a few more bits and joining the upper and lower parts of the front bulhead, it was time to put the tender top together. I have to say I struggled mightily with this, not because of any faults with the kit, just me getting it wrong. It took three attempts to get the first side, back and rear top plate soldered square! You'd think I'd never done this before. Sometimes you have a bad day at the office. Any way here's the completed top from the underside. The bottom play goes on last do a lot of the soldering can be done from the inside. This makes for an easy life cleaning up top, but I still spent time tidying up inside before putting the bottom on. Yeah I know, anal.

Still, I'm doing this for fun, so who cares about the earlier struggles when you get to here.

The bunker from the front. A little bit of filling is in order where the solder did not run, but that will be done later.

And from the rear. The instruction suggest adding the corridor roof and intermediate bulkhead before the left side, but I added the side and front bulk first. I had no problem then adding the corridoor roof and finally the bulkhead. A deviation at last!

And one or two shots screwed to the frames and chassis.

Did I say one or two shots? I meant six. The 2 thou brass weather cover on the corridor connection has taken a battering, so I'll take it off and re-do it. Just one or two (or six) etchings to add, then the remaining castings to finish it.

Cheers,

Peter

Still, I'm doing this for fun, so who cares about the earlier struggles when you get to here.

The bunker from the front. A little bit of filling is in order where the solder did not run, but that will be done later.

And from the rear. The instruction suggest adding the corridor roof and intermediate bulkhead before the left side, but I added the side and front bulk first. I had no problem then adding the corridoor roof and finally the bulkhead. A deviation at last!

And one or two shots screwed to the frames and chassis.

Did I say one or two shots? I meant six. The 2 thou brass weather cover on the corridor connection has taken a battering, so I'll take it off and re-do it. Just one or two (or six) etchings to add, then the remaining castings to finish it.

Cheers,

Peter

warren haywood

Western Thunderer

Now that IS something else Peter

P A D

Western Thunderer

Thanks Mick, Warren and Tony.

I've added the vent pipes to the rear of the front bulkhead which complete the bunker. Didn't realise that the camera had focused at the rear end, leaving the front slightly blurred.

At the front, the brake, water scoop, water valve levers, water level gauge and left hand shovel plate side gave all been fitted.

It still need some attention here and there with the scraper and scratch brush, but I've broken it's back now. Just the springs, shackles, tank top castings and streamline fairing to go on to complete.

Then I'm stuck waiting for the buffer stocks, because Mick Roffe is too busy doing a superb job on the Bulleid light Pacific to send them.

Cheers,

Peter

I've added the vent pipes to the rear of the front bulkhead which complete the bunker. Didn't realise that the camera had focused at the rear end, leaving the front slightly blurred.

At the front, the brake, water scoop, water valve levers, water level gauge and left hand shovel plate side gave all been fitted.

It still need some attention here and there with the scraper and scratch brush, but I've broken it's back now. Just the springs, shackles, tank top castings and streamline fairing to go on to complete.

Then I'm stuck waiting for the buffer stocks, because Mick Roffe is too busy doing a superb job on the Bulleid light Pacific to send them.

Cheers,

Peter

P A D

Western Thunderer

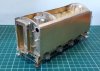

Now that I've got the streamlined fairing on the bunker, it's now looks like an A4 corridor tender as opposed to an A3 one.

This raised a couple of issues regarding the instructions, which the F7 boys might want to amend.

First on page 9 of the instructions it says "Fit the division plate angle piece (T58) to the top of the division plate." Part T58 is a half etch riveted strip, above part T59 on fret 3. T59 is a plain strio for the top of the rear bulkhead. However, a photo in Yeadon's volume on the A4, shows the strip on the division plate to be a plain and the one on the rear bulkhead riveted. The plan drawing in the instructions also show this to be the case, so it looks like the either text has it wrong or the numbering on the etch is reversed. In any case, I had already fit the riveted strip to the division plate earlier, so off it came .

Second, to fit the streamlined fairing to the top of the bunker, the etched beading at the top edge needs to be completely removed on the right side and partially removed on the left. If you don't do this I can't see how you can achieve anything like a smooth joint where the fairing etch meets the side etch. On the left hand side the beading remains between the fairing at the front and the division plate . The plain strip on the division plate and riveted strip on the top of the rear bulkhead are evident in this shot. There are some short supports to be added to the corridor top and the fairing, in line with the 2nd, 3rd, 4th and 5th vertical rivet strips on the corridor side. The water pick up covers, tank filler and rear corridor covers have also been fitted.

Here's a better shot of the tank vents.

And a view of the tank top castings.

This shows the the fairing above the corridor and the need for the supports on the prototype, still to be added.

Here are a couple of shots showing the corridor connection weather sheet after replacing the first effort, damaged during handling. It still needs some tidying up, as do one of two other areas.

And a view from the other side. Access to the corridor window should be possible from the underside after painting to fit the glazing.

Further cleaning/tidying up is needed but I'm getting there. Just the springs , shackles, brake and steam pipes still to add, and of course the buffers. For the draw bar, I will probably do the same as I did in the A3, with a pin on the tènder and draw bar screwed to the loco.

I'll take a comparison shot with the A3 tender after I've cleaned it up. It's been some months since its last clean and it is noticeable tarnished compared to this one. When I put it next to Richard Lambert's A3 on the F7 stand at Doncaster, I was able to say "mine's shinier than yours". Well not any more. Always makes me smile when people comment on some fabulous build, that it's too nice to paint. Yeah, for about a week if it's brass!

Cheers,

Peter

This raised a couple of issues regarding the instructions, which the F7 boys might want to amend.

First on page 9 of the instructions it says "Fit the division plate angle piece (T58) to the top of the division plate." Part T58 is a half etch riveted strip, above part T59 on fret 3. T59 is a plain strio for the top of the rear bulkhead. However, a photo in Yeadon's volume on the A4, shows the strip on the division plate to be a plain and the one on the rear bulkhead riveted. The plan drawing in the instructions also show this to be the case, so it looks like the either text has it wrong or the numbering on the etch is reversed. In any case, I had already fit the riveted strip to the division plate earlier, so off it came .

Second, to fit the streamlined fairing to the top of the bunker, the etched beading at the top edge needs to be completely removed on the right side and partially removed on the left. If you don't do this I can't see how you can achieve anything like a smooth joint where the fairing etch meets the side etch. On the left hand side the beading remains between the fairing at the front and the division plate . The plain strip on the division plate and riveted strip on the top of the rear bulkhead are evident in this shot. There are some short supports to be added to the corridor top and the fairing, in line with the 2nd, 3rd, 4th and 5th vertical rivet strips on the corridor side. The water pick up covers, tank filler and rear corridor covers have also been fitted.

Here's a better shot of the tank vents.

And a view of the tank top castings.

This shows the the fairing above the corridor and the need for the supports on the prototype, still to be added.

Here are a couple of shots showing the corridor connection weather sheet after replacing the first effort, damaged during handling. It still needs some tidying up, as do one of two other areas.

And a view from the other side. Access to the corridor window should be possible from the underside after painting to fit the glazing.

Further cleaning/tidying up is needed but I'm getting there. Just the springs , shackles, brake and steam pipes still to add, and of course the buffers. For the draw bar, I will probably do the same as I did in the A3, with a pin on the tènder and draw bar screwed to the loco.

I'll take a comparison shot with the A3 tender after I've cleaned it up. It's been some months since its last clean and it is noticeable tarnished compared to this one. When I put it next to Richard Lambert's A3 on the F7 stand at Doncaster, I was able to say "mine's shinier than yours". Well not any more. Always makes me smile when people comment on some fabulous build, that it's too nice to paint. Yeah, for about a week if it's brass!

Cheers,

Peter

Peter Cross

Western Thunderer

I've yet to attack one of the top league kits. Hopefully that will change next year when I get to build my M7. In the meantime I'll continue pulling out my follicles (hair already gone), on my Oakville jubilee.

Nice work Peter, I particularly like the bellows.

Nice work Peter, I particularly like the bellows.

P A D

Western Thunderer

Ahhh, the joys of Jekyll and Hyde kits.

I built the earlier A3 version for the demo model, parts T55-59 were not used, hence my mistake. My apologies and well spotted, the instructions have been amended

MD

No worries Mick.

Just send me a W1 and we'll call it quits.

JB as we all know, good kits don't guarantee good models. If you can't make a good model from a crap kit, then you probably won't make one from a good kit.

On the other hand if you can build good models from poor kits, you will find it a whole lot easier and more enjoyable process with a good kit. Go on treat yourself.

Dave, there's no answer to that. Hahaha.

Peter, thanks for the kind words. I've watched your builds on here and RMW, and from what I've seen, you will have a field day with the M7. As Richard Lambert said to me when I was buildng the A3, it will spoil all the lesser kits for you afterwards.

Cheers,

Peter

oldravendale

Western Thunderer

Apologies from me too. As I did the proof reading after Mick did the test build and wrote the instructions we should have got that right between us.Ahhh, the joys of Jekyll and Hyde kits.

I built the earlier A3 version for the demo model, parts T55-59 were not used, hence my mistake. My apologies and well spotted, the instructions have been amended

MD

Brian

P A D

Western Thunderer

Hi Brian,

As I said to Mick, it's no problem.

For the supports above the corridor roof for the fairing, I decided to solder on a length of spare etch, then cut and fettle up. One of the etched supports is on the ledge to the right of the lifting ring. It would be sod to hold that while it was soldered.

All four done and dusted.

The springs and shackles have now been fitted on both sides. The shackles were soldered on the inside with 145 and the springs were glued. Again the stubs inside the frame need grinding back to avoid fouling the wheels.

The new castings for the axle boxes are much better than the ones on the A3 tender.

The hook for mounting the buckeye is an etched laminate for soldering in place. I decided to make one from nickel silver that could be pinned and sprung to make it more user friendly.

And with the buckeye in place. The screw coupling on the left will be stowed on a hook to the right of the buckeye, for use with non buckeye fitted stock, as on the prototype. In this case it will only be cosmetic as is the buckeye, although it does pivot.

I've got the steam heating and brake fittings on the buffer beam, but need to make the hoses. I won't be using the rubber tube supplied.

Cheers,

Peter

As I said to Mick, it's no problem.

For the supports above the corridor roof for the fairing, I decided to solder on a length of spare etch, then cut and fettle up. One of the etched supports is on the ledge to the right of the lifting ring. It would be sod to hold that while it was soldered.

All four done and dusted.

The springs and shackles have now been fitted on both sides. The shackles were soldered on the inside with 145 and the springs were glued. Again the stubs inside the frame need grinding back to avoid fouling the wheels.

The new castings for the axle boxes are much better than the ones on the A3 tender.

The hook for mounting the buckeye is an etched laminate for soldering in place. I decided to make one from nickel silver that could be pinned and sprung to make it more user friendly.

And with the buckeye in place. The screw coupling on the left will be stowed on a hook to the right of the buckeye, for use with non buckeye fitted stock, as on the prototype. In this case it will only be cosmetic as is the buckeye, although it does pivot.

I've got the steam heating and brake fittings on the buffer beam, but need to make the hoses. I won't be using the rubber tube supplied.

Cheers,

Peter

simond

Western Thunderer

Peter,

I don’t think I agree...”If you can't make a good model from a crap kit, then you probably won't make one from a good kit.”

There are certainly people who would make a decent job of a decent kit, but through lack of knowledge, experience, or the array of tools we build up over the years, can’t hope to compensate for the worst the kit makers have to offer. And I’d hate anyone to be put off kit building because their first kit was a dog, and they gave up, or built something “unsatisfying” from it.

I hope Brian won’t mind me using his recent, highly successful, build of an Ace kit as an example. Many would have given up, and with good reason, but I think it’s unfair to say that those who would not have completed such an awful kit couldn’t have had more luck/success if they’d started with good materials.

I’d agree that it’s probably more fun starting with a good kit though.

I was lucky, my second kit was a Finney 47xx... learned a lot building that!

Best

Simon

I don’t think I agree...”If you can't make a good model from a crap kit, then you probably won't make one from a good kit.”

There are certainly people who would make a decent job of a decent kit, but through lack of knowledge, experience, or the array of tools we build up over the years, can’t hope to compensate for the worst the kit makers have to offer. And I’d hate anyone to be put off kit building because their first kit was a dog, and they gave up, or built something “unsatisfying” from it.

I hope Brian won’t mind me using his recent, highly successful, build of an Ace kit as an example. Many would have given up, and with good reason, but I think it’s unfair to say that those who would not have completed such an awful kit couldn’t have had more luck/success if they’d started with good materials.

I’d agree that it’s probably more fun starting with a good kit though.

I was lucky, my second kit was a Finney 47xx... learned a lot building that!

Best

Simon

P A D

Western Thunderer

Peter,

I don’t think I agree...”If you can't make a good model from a crap kit, then you probably won't make one from a good kit.”

There are certainly people who would make a decent job of a decent kit, but through lack of knowledge, experience, or the array of tools we build up over the years, can’t hope to compensate for the worst the kit makers have to offer. And I’d hate anyone to be put off kit building because their first kit was a dog, and they gave up, or built something “unsatisfying” from it.

I hope Brian won’t mind me using his recent, highly successful, build of an Ace kit as an example. Many would have given up, and with good reason, but I think it’s unfair to say that those who would not have completed such an awful kit couldn’t have had more luck/success if they’d started with good materials.

I’d agree that it’s probably more fun starting with a good kit though.

I was lucky, my second kit was a Finney 47xx... learned a lot building that!

Best

Simon

Hi Simon,

Sorry, perhaps I didn't put it the right way. What I mean is that a good kit doesn't guarantee a good model. That is down to the builder. Having finished a model does not necessarily mean it is a good model. I've seen many a poor models made from good kits over the years.

What Brian did with the Ace kit backs up what I mean. He has made a very good model from a very poor kit, because of the ability he has as a builder. And yes those who might not have been able to do what Brian did, would most likely do better with good materials. By the same token, there are many excellent builders on here, who given the worst of kits to build, would make excellent models from them. They probably wouldn't enjoy doing it though .

Cheers,

Peter