Bit of a pick 'n' mix post this one.

Lady Margaret now has her identity thanks to some custom nameplates from Narrow Planet

Finding your own compromise

When it comes to plastic kit building it helps if you think of a line. At one end of the line you have the kit as supplied, built as per the instructions with no attention or research what so ever on the prototype itself. At the other end you have the kit, researched, wrong parts replaced or corrected and superior parts substituted, as much extra detail as you can manage. Rumney chassis kind of thing. Inevitably we all need to find our place somewhere along the line that we feel comfortable.

This place can be influenced by several factors.

Cost - adding a lot of extra parts can mount up to quite an expensive model.

Expediency - high end models take a lot longer to build. Do we have the time

Reliability - no point adding every little detail if in use you're going to knock it all off again.

Usage - if you wagon is part of a train of 30 that are only ever going to trundle past at a scale 40mph are you going to have the opportunity to notice the extra work?

Consistency - no point mixing highly detailed and basic kit builds together really.

Volume - how many models are we going to need?

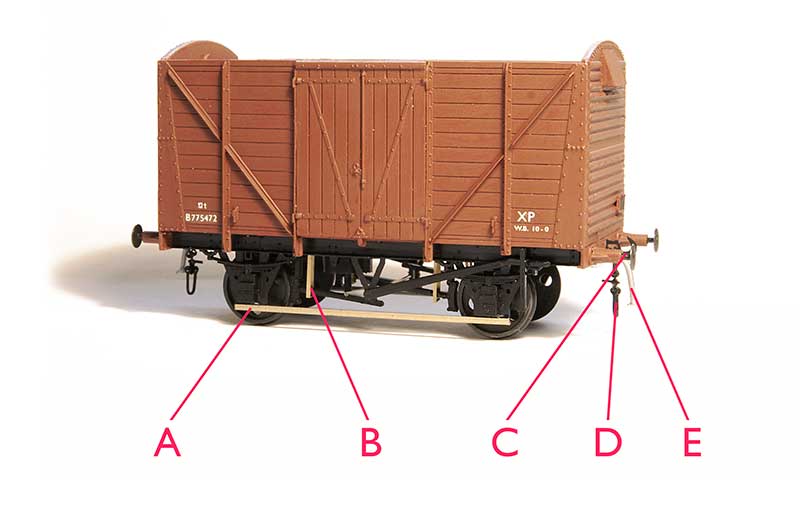

Heres my pretty much standard position along that line. The base model is a parkside kit. As mentioned elsewhere I'm not particularly worried about compensation or springing on a 10ft wheelbase wagon but i do use it for vehicles longer than 12ft wb.

A - brass tie bars. I use 0.8mm L section. the real things aren't L section but i use this for strength and you cant tell unless you turn the model upside down. In plastic kits the tie bars are a real weakness ad they are either bendy, get broken or to avoid those 2 things, massively thick.

B - break hangers from Bill Bedford - It doesn't take much to add a little finesse to the brake gear and trick the mind into thinking it's all a bit more refined that it actually is.

C - metal buffers, or in this case metal buffer heads. Unless your kit comes with metal buffers already lets be honest here, the plastic ones are going to be awful. These are MJT buffer heads.

D - couplings. A whole discussion on compromises in itself. In my case I use Smiths which i know are overscale but they are (quite) easy to use in operation.

E - brake pipe from Lanarkshire models.

Glue

I've recently been trying this stuff. Ultra Glue from MIG for etched and clear parts. Its water based so can be thinned if required and so far it seems to do the job at least as well as superglue. Its especially good for fitting name plates as while it has good grab it takes a few hours to fully harden and being water base any that creeps out can be lifted off with a wet paintbrush.

Reading

It's been an awful long time since Martin Welch treated us to his 'bible' the art of weathering. And while still essential reading things have moved on a bit, especially so in the last few years or so. Some of the paints Martin used are no longer available (Humbrol tarmac for example) but theres a whole market now of weathering paints and materials. This (rather large at over 500 pages) book is an excellent window outside of our sometimes a little comfortable railway world.

Having had a little trundle to Stourbridge shed and back for some Diesel, Class 11 shunter 12049 waits for the nod back into the yard at Brettell Road.