You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

7mm Yorky D's LT - Wagonery tales from the Met.

- Thread starter Yorkshire Dave

- Start date

Yorkshire Dave

Western Thunderer

This time I've been making some initial items in readiness for dismantling the red Hachette RT prior to repainting Lincoln green and detailing it into TG (Tring Garage) RT 4751 (OLD 538). I used to see her pounding up and down the Tring Road in Aylesbury on route 301 during the early 1970's. but I will be backdating the model to 1968/9 under LONDON TRANSPORT ownership.

I resized some 4mm decals and applied these temporarily to check the sizes. I also found and resized the BOAC and Visionhire adverstisements. I have some others for the front and rear upper deck panels and the lower rear panel.

In addition I printed up the number plates and also have the correct size LONDON TRANSPORT fleet name and RT4751 prepared for a clear decal sheet.

The decals which will present the greatest difficulty will be the ownership details, unladen weight and speed limit as these are white letters.

...... and of course there's the moquette to produce as a decal .

.

It was then I noticed the incorrect numeral 1 on the destination blinds so I made up some new ones on t'PC using the correct font ready for printing on white decal sheet. Displayed here they are vastly overscale but when printed they'll be ok.

I resized some 4mm decals and applied these temporarily to check the sizes. I also found and resized the BOAC and Visionhire adverstisements. I have some others for the front and rear upper deck panels and the lower rear panel.

In addition I printed up the number plates and also have the correct size LONDON TRANSPORT fleet name and RT4751 prepared for a clear decal sheet.

The decals which will present the greatest difficulty will be the ownership details, unladen weight and speed limit as these are white letters.

...... and of course there's the moquette to produce as a decal

.

.

It was then I noticed the incorrect numeral 1 on the destination blinds so I made up some new ones on t'PC using the correct font ready for printing on white decal sheet. Displayed here they are vastly overscale but when printed they'll be ok.

Attachments

Yorkshire Dave

Western Thunderer

The bus body has been stripped down and the castings ready for priming.

The body is held together with 7 machine screws and since Hachette Livre are a French company only they could come up with a screw head like this.......

The body is in two pieces and like 4mm EFE die cast buses I have taken apart the detail is relatively crisp once the thick paint is removed.

.......and yes

I have made up a sheet from a sample of the LT moquette used in their buses from the 1940's to the 60's for printing onto a decal sheet once it has been scaled.

I have made up a sheet from a sample of the LT moquette used in their buses from the 1940's to the 60's for printing onto a decal sheet once it has been scaled.

The body is held together with 7 machine screws and since Hachette Livre are a French company only they could come up with a screw head like this.......

The body is in two pieces and like 4mm EFE die cast buses I have taken apart the detail is relatively crisp once the thick paint is removed.

.......and yes

I have made up a sheet from a sample of the LT moquette used in their buses from the 1940's to the 60's for printing onto a decal sheet once it has been scaled.

I have made up a sheet from a sample of the LT moquette used in their buses from the 1940's to the 60's for printing onto a decal sheet once it has been scaled.

Yorkshire Dave

Western Thunderer

Following on from Pete's musings I daisy chained drilled rear destination boxes and filed them back to the edges.

Some 0.25mm acrylic sheet was cut to size and glued in place with this.

I cut some destinations I had prepared earlier, stuck them to a backing sheet and temporarily installed thus. Yes - the grey disc in the background is the top of a LT 'dolly' bus stop.

And the result is...

Yes, it does give some depth to the blinds but it is obvious they need packing out with another layer of card to bring them closer to the glass.

And Berko is spelt correctly. I noticed the 4mm destination blinds I originally scaled up have Berkhamstead instead of Berkhamsted. However it is Hemel Hempstead and not Hemel Hempsted. The quirkiness of English place names .

.

Just the remaining destination boxes to drill out.... .

.

And finally the roof ribs Pete alluded to earlier have been removed.

Some 0.25mm acrylic sheet was cut to size and glued in place with this.

I cut some destinations I had prepared earlier, stuck them to a backing sheet and temporarily installed thus. Yes - the grey disc in the background is the top of a LT 'dolly' bus stop.

And the result is...

Yes, it does give some depth to the blinds but it is obvious they need packing out with another layer of card to bring them closer to the glass.

And Berko is spelt correctly. I noticed the 4mm destination blinds I originally scaled up have Berkhamstead instead of Berkhamsted. However it is Hemel Hempstead and not Hemel Hempsted. The quirkiness of English place names

.

. Just the remaining destination boxes to drill out....

.

. And finally the roof ribs Pete alluded to earlier have been removed.

Yorkshire Dave

Western Thunderer

It does make the difference Pete ans as you say a fret for the front would be nice.

However.....

I've drilled out the remaining destination blinds including the three at the front and cleaned up the resulting holes. The arrangement below is temporary to see the effect and the glazing is held in this time by Johnson Klear (500ml bottle bought several years ago). Once set, I ran a black wash in the join. Enlargements are so cruel .

.

The green is a mix of Vallejo Black green and Zinc Green and the stripe is Buff.

The side entrance blind (and rear) - at bit wonky but prototypical

As you used to see the destination - i.e. not until it's just gone by and you realised it's the bus you wanted.

Without the reflections.....

However.....

I've drilled out the remaining destination blinds including the three at the front and cleaned up the resulting holes. The arrangement below is temporary to see the effect and the glazing is held in this time by Johnson Klear (500ml bottle bought several years ago). Once set, I ran a black wash in the join. Enlargements are so cruel

.

.The green is a mix of Vallejo Black green and Zinc Green and the stripe is Buff.

The side entrance blind (and rear) - at bit wonky but prototypical

As you used to see the destination - i.e. not until it's just gone by and you realised it's the bus you wanted.

Without the reflections.....

Yorkshire Dave

Western Thunderer

These are the first stages of making patterns for the left and right forward facing seats, here alongside the moulded seats from the model.

They are made up from 0.8 mm brass rod and scrap brass and nickel silver. The upholstery will be made up from either plasticard or chemical metal carved to shape.

They are made up from 0.8 mm brass rod and scrap brass and nickel silver. The upholstery will be made up from either plasticard or chemical metal carved to shape.

Yorkshire Dave

Western Thunderer

Oooooooh - stoppit!

Shades of Kenneth Williams - Stop messing about!

I know - there are loads to choose from - as I alluded to earlier I think a red RT is on the cards now. Was route 84 but might now be 142 or 258 ??

Having removed most of the lower saloon mounting columns naturally the upper saloon really needed attention so I went to my local independent hardware store and purchased these for use in the minidrill (which has a flexible drive). They are milling cutters which I used (with some tapping fluid provided by my neighbour) to grind out the upper parts of the upper saloon mounting columns. Initially a daunting process but became easier when I worked out the best way to hold the device to efficiently remove the material.

This is the result, not pretty by any standard as I have to tidy up some tiny nicks. Again about 10mm is left.

And the visual improvement

I also removed the top part of the front upper saloon mounting columns to eliminate the slight hump when viewed from the front.

Hopefully this should be the end of the 'heavy engineering'......

Yorkshire Dave

Western Thunderer

Now moving onto some of the smaller details......

I've made up a pair of LT 'ears' or indicators as later fitted to RTs, RF buses and early Green Line coaches (the 'modified' Green Line coaches with the light green waist stripe had a different style fitted), RMs etc.

The indicators were made up from brass tube. rod and scrap nickel silver etch. The orange surround is car head/rear light repair tape stuck onto the indicator and the inside removed to represent the frame.

I have not made the cantrail fitting bracket as these 'ears' can then be used on different buses. The bracket will be made up separately as part of the rebuild.

Then onto the rear, again car head/rear light repair tape (double layer this time) was used to make up the left indicator arrow panel and the blanking plate over the left arrow of the double arrow indicator originally fitted to the RTs.

I've made up a pair of LT 'ears' or indicators as later fitted to RTs, RF buses and early Green Line coaches (the 'modified' Green Line coaches with the light green waist stripe had a different style fitted), RMs etc.

The indicators were made up from brass tube. rod and scrap nickel silver etch. The orange surround is car head/rear light repair tape stuck onto the indicator and the inside removed to represent the frame.

I have not made the cantrail fitting bracket as these 'ears' can then be used on different buses. The bracket will be made up separately as part of the rebuild.

Then onto the rear, again car head/rear light repair tape (double layer this time) was used to make up the left indicator arrow panel and the blanking plate over the left arrow of the double arrow indicator originally fitted to the RTs.

Yorkshire Dave

Western Thunderer

Yorkshire Dave

Western Thunderer

Like the proverbial London bus - nothing for ages then three turn up at once....

.... in this case three Quainton Road Models Metropolitan Railway 6T 2 plank dropside ballast wagons acquired from Rob Pulham.

The kits look like they are of their time as the brass might just as well be armour plating . Anyway they provide me with three LT wagons for which wheels and couplers will be diverted from other projects

. Anyway they provide me with three LT wagons for which wheels and couplers will be diverted from other projects  .

.

Furthermore it will mean getting used to my new Ersa RDS 80 soldering station after a relatively new Antex TCS50 just packed up.

The last of these prototypes were withdrawn in the mid 1950s - a bit early for my 1968 LT stock - which means I'll have to have a Met loco to accompany them . Until such time, rule 1 will apply.

. Until such time, rule 1 will apply.

.... in this case three Quainton Road Models Metropolitan Railway 6T 2 plank dropside ballast wagons acquired from Rob Pulham.

The kits look like they are of their time as the brass might just as well be armour plating

. Anyway they provide me with three LT wagons for which wheels and couplers will be diverted from other projects

. Anyway they provide me with three LT wagons for which wheels and couplers will be diverted from other projects  .

. Furthermore it will mean getting used to my new Ersa RDS 80 soldering station after a relatively new Antex TCS50 just packed up.

The last of these prototypes were withdrawn in the mid 1950s - a bit early for my 1968 LT stock - which means I'll have to have a Met loco to accompany them

. Until such time, rule 1 will apply.

. Until such time, rule 1 will apply.Yorkshire Dave

Western Thunderer

Some progress today but I had forgot how much hard work some brass kits are - especially when dealing with armour plate and a perceived lack of thought by the designer for the ease of construction. You would have thought an open wagon would be relatively simple  . It also appears there was a era where there was a 'everything has to be built of brass' fixation.

. It also appears there was a era where there was a 'everything has to be built of brass' fixation.

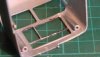

To continue - a lot of time was spent cleaning up the parts after removing them from the fret and this is the first one of the trio on it's way - at least I thought so .

.

Chassis - I've already had to make adjustments to the brake gear by slicing 3mm from the top support otherwise the brakes do not line up with the wheels. I've also noted the wheels have about 3mm lateral movement but I don't know what for? I'll be disassembling the brake gear to move it inwards after reducing the wheels lateral movement.

Body - a bit of a struggle aligning the sides as each side and end are laminated by folding over. I managed it in the end and the sides and ends were tinned, folded over, secured with bulldog clips and blasted with a blow torch. The aligning of the sides would have been made easier if there were locating tabs with holes in which to insert some rod.... see next photo. The buffer beams ends are a fold up as are the door bumpers on the chassis and both have ended up with rounded corners. The wagon end posts are a similar fold up.

Having reached this stage of the now apparent false start there are a several things I'll be altering for the next pair, and partially rebuilding this one, including the brake gear noted earlier.

- adding solder to the buffer beam outer corners and filing them square.

- make new end posts and door bumpers - again square.

Now's the time to walk away, take stock of this lot and with the aid of Percy and his Verances (good band?) make good kit's shortcomings .

.

And a final controversial observation - rather than fill every conceivable space on an etch with kit parts it would be nice if consideration was given by some some (not all) kit designers to aid alignment when having to laminate parts. But alas economics is the driver.

. It also appears there was a era where there was a 'everything has to be built of brass' fixation.

. It also appears there was a era where there was a 'everything has to be built of brass' fixation.To continue - a lot of time was spent cleaning up the parts after removing them from the fret and this is the first one of the trio on it's way - at least I thought so

.

.Chassis - I've already had to make adjustments to the brake gear by slicing 3mm from the top support otherwise the brakes do not line up with the wheels. I've also noted the wheels have about 3mm lateral movement but I don't know what for? I'll be disassembling the brake gear to move it inwards after reducing the wheels lateral movement.

Body - a bit of a struggle aligning the sides as each side and end are laminated by folding over. I managed it in the end and the sides and ends were tinned, folded over, secured with bulldog clips and blasted with a blow torch. The aligning of the sides would have been made easier if there were locating tabs with holes in which to insert some rod.... see next photo. The buffer beams ends are a fold up as are the door bumpers on the chassis and both have ended up with rounded corners. The wagon end posts are a similar fold up.

Having reached this stage of the now apparent false start there are a several things I'll be altering for the next pair, and partially rebuilding this one, including the brake gear noted earlier.

- adding solder to the buffer beam outer corners and filing them square.

- make new end posts and door bumpers - again square.

Now's the time to walk away, take stock of this lot and with the aid of Percy and his Verances (good band?) make good kit's shortcomings

.

.And a final controversial observation - rather than fill every conceivable space on an etch with kit parts it would be nice if consideration was given by some some (not all) kit designers to aid alignment when having to laminate parts. But alas economics is the driver.

Yorkshire Dave

Western Thunderer

After studying the Met diagrams again it came to pass the chassis in the kit is incorrect grrrrr.

Only after I had naively assumed it was correct, and after punching the rivets of course.... doh!

doh!

The wagon underframes were wooden and fortunately I had some Ambis wagon underframe strapping in the spares box left over when I was making the LCDR and LBSC wagon underframe patterns. So I set to work filing off the rivets and soldered the strapping to the underframes.

Modified (left) and unmodified (right) underframes.

Next came the wagon body dropside hinges and strapping. The hinges (centre left) as supplied were designed to wrap around 0.7mm wire after annealing.... Ha ha - not so with this battleship brass which would be better suited on a Dreadnought - the marine variety not the coaches!

Rather than struggle with annealing and bending this around brass wire I cut the bottom panel off (centre right).

These were then soldered to the wagon body using a blow torch.

I then tinned some 0.8mm brass wire and soldered this (with a soldering iron) to the hinge plate to form the hinge.

The wire was cut and the process repeated for the remaining hinges

The cut edge was cleaned up and the result is below. I also added some gap filling solder to the buffer beam outer corners and filed them square.

And the weapon of choice is this..... . The small gas cylinder had run out so I fitted the burner to a standard campingaz can.

. The small gas cylinder had run out so I fitted the burner to a standard campingaz can.

Now for some experiments. I tried to see if I could make the hinges by soldering the wire to the hinge plate before installation. As can be seen - not so successful. The bottom item is an end stanchion folded up - somehow methinks I'll be making some new ones.

And now to earn some points. And what do points mean......? PRIZES .

.

The brake etches provided in the kit are supposed to be laminated....? errrrrr - and without cutting, how is this achieved? Answers please on a postcard to Mrs Trellis of Wales.

errrrrr - and without cutting, how is this achieved? Answers please on a postcard to Mrs Trellis of Wales.

Only after I had naively assumed it was correct, and after punching the rivets of course....

doh!

doh!The wagon underframes were wooden and fortunately I had some Ambis wagon underframe strapping in the spares box left over when I was making the LCDR and LBSC wagon underframe patterns. So I set to work filing off the rivets and soldered the strapping to the underframes.

Modified (left) and unmodified (right) underframes.

Next came the wagon body dropside hinges and strapping. The hinges (centre left) as supplied were designed to wrap around 0.7mm wire after annealing.... Ha ha - not so with this battleship brass which would be better suited on a Dreadnought - the marine variety not the coaches!

Rather than struggle with annealing and bending this around brass wire I cut the bottom panel off (centre right).

These were then soldered to the wagon body using a blow torch.

I then tinned some 0.8mm brass wire and soldered this (with a soldering iron) to the hinge plate to form the hinge.

The wire was cut and the process repeated for the remaining hinges

The cut edge was cleaned up and the result is below. I also added some gap filling solder to the buffer beam outer corners and filed them square.

And the weapon of choice is this.....

. The small gas cylinder had run out so I fitted the burner to a standard campingaz can.

. The small gas cylinder had run out so I fitted the burner to a standard campingaz can.

Now for some experiments. I tried to see if I could make the hinges by soldering the wire to the hinge plate before installation. As can be seen - not so successful. The bottom item is an end stanchion folded up - somehow methinks I'll be making some new ones.

And now to earn some points. And what do points mean......? PRIZES

.

. The brake etches provided in the kit are supposed to be laminated....?

errrrrr - and without cutting, how is this achieved? Answers please on a postcard to Mrs Trellis of Wales.

errrrrr - and without cutting, how is this achieved? Answers please on a postcard to Mrs Trellis of Wales.

Yorkshire Dave

Western Thunderer

These kits are becoming a slow job with having to make replacement parts albeit from 2.5mm square styrene...

Today has seen the addition of the dropside catches at each upper corner and the making of four new end stanchions and door bangers.

The end stanchions and door bangers were mede up from 2.5mm square styrene and filed to shape. The fixing face was roughed up and stuck to the brass with superglue. Holes were drilled in the end stanchions for 0.8mm wire, which was glued, cut back and filed. Holes were also drilled in the door bangers to represent the countersunk bolts.

In addition the Met buffers were made up and fixed to the bufferbeam.

Next will be the springs and axleguards..... another long job as the cast axlebox and spring have to be separated and faffed about with in order to make them fit....

job as the cast axlebox and spring have to be separated and faffed about with in order to make them fit....

Today has seen the addition of the dropside catches at each upper corner and the making of four new end stanchions and door bangers.

The end stanchions and door bangers were mede up from 2.5mm square styrene and filed to shape. The fixing face was roughed up and stuck to the brass with superglue. Holes were drilled in the end stanchions for 0.8mm wire, which was glued, cut back and filed. Holes were also drilled in the door bangers to represent the countersunk bolts.

In addition the Met buffers were made up and fixed to the bufferbeam.

Next will be the springs and axleguards..... another long

job as the cast axlebox and spring have to be separated and faffed about with in order to make them fit....

job as the cast axlebox and spring have to be separated and faffed about with in order to make them fit....

Yorkshire Dave

Western Thunderer

An attempt has been made at adapting some Andrew Stadden figures I had previously painted as there are no suitable figures available to represent LT engine crew.

From my observations the available figures are either pre-group - wrong headgear; a few inter-war - always with jackets and BR - trousers are always with bibs. The photos in the LT books I have show the LT crew with lightweight jackets and trousers or crew with shirts and trousers and it's the latter which has been proving difficult to find a suitable figure for.

So I removed the paint from the figures and altered them slightly to more late 1960's appearance. The easiest conversion was the figure on the left who had his nose flattened slightly and the figure on the right took a lot longer to prepare and the braces had to be removed. Anyway here are the results.

Somehow, despite working on a filthy footplate, shirts always seem to have remained clean.

From my observations the available figures are either pre-group - wrong headgear; a few inter-war - always with jackets and BR - trousers are always with bibs. The photos in the LT books I have show the LT crew with lightweight jackets and trousers or crew with shirts and trousers and it's the latter which has been proving difficult to find a suitable figure for.

So I removed the paint from the figures and altered them slightly to more late 1960's appearance. The easiest conversion was the figure on the left who had his nose flattened slightly and the figure on the right took a lot longer to prepare and the braces had to be removed. Anyway here are the results.

Somehow, despite working on a filthy footplate, shirts always seem to have remained clean.

Yorkshire Dave

Western Thunderer

Did you ever source suitable buffers for the brake van?

I did source some buffers at Reading.... LMS loco standard round head (but not 17th century though!) as they have the all important step plate. They have a whitemetal body, are sprung and have and turned steel heads.

They were cleaned, painted, heads blackened and installed today.

In addition to the buffers the W irons, axle boxes, brake shoes, wheels and couplers were installed. The brake rods and and associated gubbins are yet to be added along with the verandah safety rails/bars.

The three oiks or troublesome trucks (i.e. the Met ballast wagons) have been consigned to the back of the class whilst the brake van provides a respite......

Yorkshire Dave

Western Thunderer

Here it it - eventually - virtually complete as it requires the tare weight decals.

The brake gear has been fitted and I made up some new safety rails as the ones supplied are all in the raised closed position. The new ones were made from 0.5mm brass wire and some Weinert handrail knobs left over from the HO days.

On my model only one safety rail is raised and the remaining three are in the dropped open position.

The brake gear has been fitted and I made up some new safety rails as the ones supplied are all in the raised closed position. The new ones were made from 0.5mm brass wire and some Weinert handrail knobs left over from the HO days.

On my model only one safety rail is raised and the remaining three are in the dropped open position.

Yorkshire Dave

Western Thunderer

Yorkshire Dave

Western Thunderer

As the header implies progress is starting to fall into the geologic time zone as it is the thought of the work required to complete the chassis for these trucks. Namely the axleboxes and springs....

......and whilst delaying the inevitable, a second body (BW.81) has been painted and lettered. Buffers have also been added - and the self contained buffers are correct for these 1866 - 1882 built vehicles.

Debris has been added to the interiors.

One has also since received some couplers which require blackening.

......and whilst delaying the inevitable, a second body (BW.81) has been painted and lettered. Buffers have also been added - and the self contained buffers are correct for these 1866 - 1882 built vehicles.

Debris has been added to the interiors.

One has also since received some couplers which require blackening.

Yorkshire Dave

Western Thunderer

With grateful thanks for Tony's observations the bus crews are now sporting the correct PSV registration badges (red - driver, green - conductor) and the country area conductor's ticket machine now resembling something like a Gibson.

And yes I did purchase a second RT - to be ripped apart as the country area RT 4751 (OLD 538) - and finished as a central area RT 2528 (LYF 177).

- to be ripped apart as the country area RT 4751 (OLD 538) - and finished as a central area RT 2528 (LYF 177).

Oh no! seeing double....

And yes I did purchase a second RT

- to be ripped apart as the country area RT 4751 (OLD 538) - and finished as a central area RT 2528 (LYF 177).

- to be ripped apart as the country area RT 4751 (OLD 538) - and finished as a central area RT 2528 (LYF 177).

Oh no! seeing double....

Yorkshire Dave

Western Thunderer

Sorry Dave we've hi-jacked your thread mate

Sorry Dave, went off on one...

No worries chaps.....

Back onto the Met ballast wagons and these are slowly getting there and in the immortal words of E F Benson's George "Georgie" Pillson (Mapp & Lucia novels) - How tiresome..... Added to my heavy weather in building what is a simple vehicle.

Being a bit P'd off with the axle boxes, W irons, etc....... on one of the chassis I decided to remove the fold up etched W irons. Incidentally I checked the spacing of these and they are more suited to 5' or 5'6'' gauge

????

???? Anyway I cut some 2.5mm square styrene and inserted a double layer into the chassis to support new ABS axle guards and springs etc a bit crude but it works.

Another shortcoming of the kit, and like a fool

I punched the rivets and built the wagons, is the interior detail.

I punched the rivets and built the wagons, is the interior detail.

So I set about cutting strips of Tamiya masking tape to represent the interior bracing.

Now I know what to do next time.... No more brass wagon kits

- I'll think I'll be scratch building these in the future.

- I'll think I'll be scratch building these in the future.And the trio thus far. The centre wagon is the one with the ABS W iron, spring and axlebox castings. There's no logic whatsoever in my approach as I realise the centre truck requires the brake safety loops.....