Suffolk Dave

Western Thunderer

Impressive work going on here! Thanks for sharing Herbie

Hi Brian,Herbie,

Assuming your CAD can be output as an .STL file, upload it to https://craftcloud3d.com/ and view the many types of material offered for printing by a variety of vendors. Whether the prices are to your liking or not is another matter.

For some driving wheel spoked centres I have used:

"Somos® Taurus which has high thermal and mechanical properties along with superior strength, high accuracy, and exceptional surface finish."

Specify that 'supports' be attached to the rear side of the wheel (so as to leave the front of spokes unmarked).

Brian McK.

View attachment 177494

That’s a very brave move there George but you have done a great job on it! I’m glad it has come back together so well.Adventures with a split chassis.....

Well work has once again taken over.... The first week back lulls you into a false sense of security after the shutdown but then week 2.... It didn't help modelling progress this week particularly having to drive to Sheffield and back in a day for a customer meeting..... Long day......

However some progress has been made at the sidings.....

Firstly springs.... I've started the uneviable job of making the leaf springs for the class 73 (12 in total )

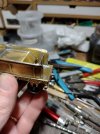

View attachment 177892

Starting with lots of fine stripwork cut to ever decreasing lengths (all tinned first)

View attachment 177893

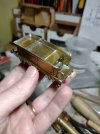

The longest leaf is then solderd into position on two wires in a very 'hightech' jig

View attachment 177894

Then the leafs sweated together..... one spring done 11 to go

But then I got distracted......

During the pandemic I turned 30 so as we couldn't all meet up my family clubbed together and bought me a locomotive kit....of a GER E22 class (J65 to those of you who only speak LNER).... Which I built later that year

View attachment 177900

It was a bit of a step up for me as it was the first time I had build a loco chassis that ran smoothly and the first time I had built anything with compensation..... I think the two are linked..... Anyways it ran for most of 2021 on my Skeetsmere mk2 layout until it was disassembled for painting..... And learning how to use an airbrush

Then I decided to move to EM gauge and the E22 was shelved pending conversion.....

So on Sunday I thought to escape from springs why not convert it to EM?

The easy thing to would be of course just put longer axles in and some spacer washers in and be done with but no.....

View attachment 177906

What I decided would be a great idea would be to literally spilt the chassis into 2 pieces then solder in some new frame spacers..... I must have been mad....View attachment 177907

Surprisingly when I put the pieces back it the jig it went together rather well... With a new front compensation beam

View attachment 177908

And now it is rolling perfectly and I've got the body to fit back on..... Chassis now needs the brake gear adjusted and painted before it rejoins the body.... And then somehow I need to tone down the garish blue.... It's the right shade but just too intense for a 4mm scale model....

View attachment 177910

So until next time.... Happy modelling!

Oh dear that thought is going to give me nightmares for weeks.....

The thought of lining a locomotive scares me witless.... I know I've read a couple of excellent books done practice runs and got a couple of very nice bow pens to use..... Even so bringing myself to bring paint to model is something I shy away from every time I contemplate it....

Not sure why cos it's GER blue.... That should be much easier that something like SECR green.....