adrian

Flying Squad

Things have been ticking along but it's all the small details so I don't seem to have much to show for my efforts this week.

I've moved onto the boiler and as mentioned this is a resin/plastic casting. It needed a little fettling around the splashers but overall it was nice and square and fitted very well.

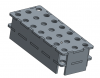

Once I was happy with the fit I moved onto the detailing as some improvements were in order. The washout plugs were lost-wax brass castings, whilst reasonable they were quite shallow and they would need a bit of filing to get flush I decided to make my own instead.

I drilled a series of 1/16" holes in a bit of brass strip and then cut out in to squares. A short length of 1/16" brass rod was soldered in. With the base being square it was a few moments works with a 6" file to file the rod square. The bottom 4 in this photo have been squared off, the height is such that they can be inserted and glued from the rear of the firebox.

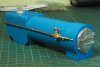

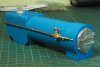

The other item that needed drastic action was the ejector (?) on the side of the boiler. First look it didn't look right for some reason and it took a little while to decide what need fixing. Basically it was too long, the 3F has quite a short smokebox and the front part of the ejector on the smokebox should line up with the chimney centre line, but this then placed the main body too far back. Measuring up from the drawing it should be about 2' 8" in length (full size!) whereas I measured up the supplied casting as 3' 7" so nearly a scale foot too long.

There are plenty of spares components in the kit and I think from all the photos I have seen the 3F always had the ejector on the right hand side but in the kit there is a lefthand ejector and a right hand ejector. So the photo below shows the cut and shut right hand ejector (bottom) verses the supplied left hand ejector (top). It wasn't a simple cut and shut either it needed 2 slices removing either side of the union joint half way down so make sure that was in the right place.

Once that was done a few other fittings, hand rails etc were fitted so this is the current status. The pipework at the rear of the firebox has been left over length at the moment. The next job being sorting out out drilling the cab spectacle sheet for pipes and hand rails.

My thanks to @Thirtysecond for the recommendation for glue

An amazing adhesive

I have used this for sticking everything to the boiler and I'm very happy with it. It seems to work well on the plastic, I know the recommendation was application of activator on both surfaces and then glue on both surfaces. I did it slightly differently, for example the handrail knobs I would use a cocktail stick to fill the drilled hole with the glue, I would then spray the handrail knob with the activator and then push it into place, it took about 15 - 20 seconds to go off so it was a nice little bit of wriggle time to make sure it was in the right place and not too long that it was no problem just holding it in place with fingers whilst the glue went off.

I've moved onto the boiler and as mentioned this is a resin/plastic casting. It needed a little fettling around the splashers but overall it was nice and square and fitted very well.

Once I was happy with the fit I moved onto the detailing as some improvements were in order. The washout plugs were lost-wax brass castings, whilst reasonable they were quite shallow and they would need a bit of filing to get flush I decided to make my own instead.

I drilled a series of 1/16" holes in a bit of brass strip and then cut out in to squares. A short length of 1/16" brass rod was soldered in. With the base being square it was a few moments works with a 6" file to file the rod square. The bottom 4 in this photo have been squared off, the height is such that they can be inserted and glued from the rear of the firebox.

The other item that needed drastic action was the ejector (?) on the side of the boiler. First look it didn't look right for some reason and it took a little while to decide what need fixing. Basically it was too long, the 3F has quite a short smokebox and the front part of the ejector on the smokebox should line up with the chimney centre line, but this then placed the main body too far back. Measuring up from the drawing it should be about 2' 8" in length (full size!) whereas I measured up the supplied casting as 3' 7" so nearly a scale foot too long.

There are plenty of spares components in the kit and I think from all the photos I have seen the 3F always had the ejector on the right hand side but in the kit there is a lefthand ejector and a right hand ejector. So the photo below shows the cut and shut right hand ejector (bottom) verses the supplied left hand ejector (top). It wasn't a simple cut and shut either it needed 2 slices removing either side of the union joint half way down so make sure that was in the right place.

Once that was done a few other fittings, hand rails etc were fitted so this is the current status. The pipework at the rear of the firebox has been left over length at the moment. The next job being sorting out out drilling the cab spectacle sheet for pipes and hand rails.

My thanks to @Thirtysecond for the recommendation for glue

An amazing adhesive

I have used this for sticking everything to the boiler and I'm very happy with it. It seems to work well on the plastic, I know the recommendation was application of activator on both surfaces and then glue on both surfaces. I did it slightly differently, for example the handrail knobs I would use a cocktail stick to fill the drilled hole with the glue, I would then spray the handrail knob with the activator and then push it into place, it took about 15 - 20 seconds to go off so it was a nice little bit of wriggle time to make sure it was in the right place and not too long that it was no problem just holding it in place with fingers whilst the glue went off.

I can spare a few moments to report progress on the pickups.

I can spare a few moments to report progress on the pickups.