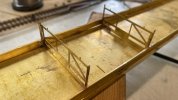

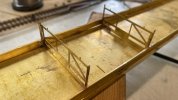

I have attached the queen posts and sole bars to the underside of the floor, making sure the queen posts are straight and soldered to both floor and sole bars. The next step is to test fit the floor to the body and line up the buffer plates.

The model is starting to take shape

One important reminder in the instructions - keep checking the body and floor are the right way round! This applies to brake ends but also in this case both toilets are at one end of the coach. An easy mistake to make when fitting the roof as well, water tanks are always associated with toilets.

The tumblehome on the sides makes the body a tight fit over the floor. It is therefore important to let the glue cure fully before attempting to put the body over the floor uprights as it is easy to undo the bond. (I know from experience). EDIT: It has happened again on one side.

Malcolm suggests fitting any lengthwise partition, such as in a corridor coach before continuing with the underfloor fittings. In the case of an open third I will leave the interior until later as it could get damaged.