JimG

Western Thunderer

Jamie,

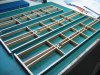

These coach cast coach parts look really excellent when made up. It's also given me ideas for milling sides which are longer than the "X" movement of my table.

There's also the satisfaction of knowing that you can churn out umpteen coaches if you so wish - almost at the press of a button on a casting machine.

Jim.

What swung it for me was the fact that the coaches I wanted to model had a curved detail to the top of each window and door panel rather than a straight horizontal cut between rounded corners. The large scale meant this would need addressing to my mind; hand working would mean each aperture would need to be filed back to shape with a consistency I was just incapable of. Etching would require drafting skills I also don't have so I tried this casting business as an experiment. I thought about casting myself but can't think I would have been any good at that either so bit the bullet, and as said am pleased I did.

These coach cast coach parts look really excellent when made up. It's also given me ideas for milling sides which are longer than the "X" movement of my table.

I will have enough bits for most of a decent rake; some coaches had different window spacings (3rd/ 1st etc) and the differing sections will each either require a new mould (all the blanks have been machined ready) if needed in numbers, or scratchbuilt originals just used 'in the raw' if not.

Was it worth it? To me, yes it was to get the degree of consistency I don't have the skills or attention span to get in other ways.

There's also the satisfaction of knowing that you can churn out umpteen coaches if you so wish - almost at the press of a button on a casting machine.

Jim.