A quick progress report from chasers corner.

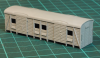

A lucky escape to start with - I folded up one side of the body before remembering I had to press out the rivets - a gentle bend back, just enough to allow access for the rivet press, and I got both sides done fairly quickly. Folded back up again, I put the ends loosely in place and discovered that I had a 1mm gap between the body side and the half etched angle iron on the end (ie the ends were over width). A large chunk of that is down to the way I folded said angle iron round - I ended up flattening it back out again, using an olfa cutter right on the corner and reforming it. Original bend on the left, tighter version on the right.

The tighter bend pulled back about 0.5mm and I was wondering what to do about the last bit. A look through Paul Bartlett's site showed that some vans had what appears to be an extra piece of strapping under the angle iron in the corners. I paid for a couple of downloaded photos and from what I can see, the additional metal adds extra width to the angle iron. That was good enough for me, I made some strips from 0.25mm thick nickel silver and soldered them inside the angle iron (this one could do with a stroke of a file to get rid of the slight taper).

The strips extend all the way to the bottom of the angle, the excess is just filed off as per the photos. The angle has taken a bit of battering really, some subtle reshaping with solder towards the end of the build is required.

I've also prepped the chalk boards and ventilators for the sides, shown here with the ends which now fit the width of the body.

Hoping for a good day of soldering tomorrow.

Steve

So some time to finish my new painting booth, decide on livery and find transfers etc.

So some time to finish my new painting booth, decide on livery and find transfers etc.