Peter Cross

Western Thunderer

Time to start cutting.

I cut out with my piercing saw the parts that were already blanked. I have decided to go with one of the Adam’s series, that have the square cut outs. It'll be double digit number.

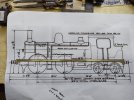

The front profile drawing is pretty poor. I will see if the other one is better. I did manage to use it to do the cab front and rear.

The footplate had the centre cut out, I did this with the saw and scrawker.

With a little time to spare I filed the sides. This came up quite nicely, checking all verticals were perpendicular to the bottom edge. the top of the cab will be lowered, later, there's not a lot of strength at the cab opening.

Before anything gets soldered, I need to make some more bits, in no particular order, buffer planks, hanging irons, boiler, smoke box, and frame spacers that need to be about 2.5 millimetres wider than the ones I originally cut.

I cut out with my piercing saw the parts that were already blanked. I have decided to go with one of the Adam’s series, that have the square cut outs. It'll be double digit number.

The front profile drawing is pretty poor. I will see if the other one is better. I did manage to use it to do the cab front and rear.

The footplate had the centre cut out, I did this with the saw and scrawker.

With a little time to spare I filed the sides. This came up quite nicely, checking all verticals were perpendicular to the bottom edge. the top of the cab will be lowered, later, there's not a lot of strength at the cab opening.

Before anything gets soldered, I need to make some more bits, in no particular order, buffer planks, hanging irons, boiler, smoke box, and frame spacers that need to be about 2.5 millimetres wider than the ones I originally cut.