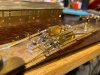

Apologies for the lack of progress, work is really busy and I'm knackered by the time I get home to do anything. This friday was different, an early finish and a jaunt up to Tewkesbury. I took all my engines that I'd built during the last year to test them on Barrow Road.

Std Class 7

Std Class 5

GWR 2251

GWR 56xx * 2

GWR 42xx

The problem with having a layout that's a metre long is...that it's just a meter long. Robin Whittles layout is much..much longer. So first my thanks to Robin for giving up some time to allow these engines the freedom of his roads.

The results were not as expected...

2251 which runs like a dream on the plank was a complete loss, stuttering all over the place and in some places refusing to run at all. So, work to be done on the pick ups, when it did run it was really smooth.

56xx * 2 ditto. Interestingly though, the better of the two was the Comet chassis. This is probably down to the fact I laid the pick ups out differently on this.

Std class 7 - Brittania - runs really well at full throttle and held the road well, but suffers from a lack of traction. I suspect that the front bogie and rear pony are set too high to allow the drivers to fully grip the rails. On the positive side no wheels came off the track and it didn't stall when crawling. So an encouraging start to the end of a long project.

GWR 42xx, which ran ok on the plank - nothing special - was the star performer! Ran like the proverbial Swiss watch, really pleased with this. Never stalled and didn't fall in the water either. Back of the net Brian!

I didn't run the Std cl 5, I'd had enough humiliation for one day. And as you know, the front bogie still requires attention to allow all the wheels to turn. So this may also require more weight over the front as well as a new bogie. This has now been received form the etchers (thank you Justin Newitt for doing that for me) and needs to be made up and fitted.

So not a complete dissaster, and nothing that's unsolvable. So, my current thinking is to tackle the Brit first, as that's going to need a fair bit of soldering done to it. Then a good think on how to do the pick ups for 2251 and the 56's. Any ideas would be appreciated.

My thanks again to Robin Whittle for a superb day out and to Morgan Gilbert for pointing me in the right direction to solve the many issues. This was our first meeting in nearly 16 months and I've really missed the contact with my friends. Thank you both for making it such a great time. And lastly, it would be remiss of me not to thank Liz (Rob's wife) for the superb cake - even if it wasn't a fruit cake - and the raspberry iced tea.

Looking forward to next month when we do it all again, assuming we don't find ourselves in another lock down!

Stay safe, it really is still out there.

Mike

. I have to admitt to enjoying my job at CAF.

. I have to admitt to enjoying my job at CAF.

- and don't forget to polish off the machining marks on those sprung heads, it makes a world of difference to the appearance.

- and don't forget to polish off the machining marks on those sprung heads, it makes a world of difference to the appearance.