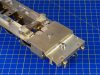

Little more work on the WS 72xx. The rear end brake rods need finishing once the weigh shaft and 3D printed bearings go in.

The footplate and raised area above the cylinders is new, the front deck is from the kit, watch out as it's a bit long so you need to trim it a bit, from the rear is the best but not too much as the holes for the small hand rails won't line up with the front steps.

I found the rear valance extensions too short by about 4 mm, the joint is a half etched lap joint so they were soldered up the right length and a thin flat plate soldered into the half etch gap and dressed smooth.

I couldn't find any rear guard irons in the etches but it's no trouble to whip two new ones up. The cylinder wrappers were replaced with thinner 10 thou ones, easier to form to shape that's all.

The slide bars come affixed to the rear piston cover and stuffing gland, the piston rod is 2 mm but the hole is 2.3 mm, I drilled it out to 2.5 and sleeved it with thin bore brass tube.

Pressure relief valves are on their way (not supplied in the kit as far as I can see) and will go in the pre drilled holes front and rear.

I think the turned piston and valve covers are generic, my front piston covers were much too big so needed turning down in the lathe, same for the front tail rod cover, it's too long and fouls the front foot plate as it drops down, took 3 mm and smoothed the edges and all good.

Watch the rocker arm covers they actually cut into the front splasher quite a bit, a small detail easily missed. The castings are to scale. but due to the narrower frames they don't meet the frame extension above the footplate to match, one of those modelling compromises.

Only the front splasher is neat and formed, even then only the front 3/5 is visible once the tanks go on. The rest are completely hidden from above so no need to make them look neat.

Revised 3D printed front sand boxes now fitted, width adjusted to suit narrower frames and filler lids changed to suit 72xx.

.

.