Before you can define fit for purpose you have to define costs, time and situation/location.

The last is probably the most important, parts fit for purpose on a sprawling garden railway may not be for a depot layout where the model is the main focal point, for simplicity we'll stick with the latter.

Time is the big killer, people like to spend two hours fettling and cleaning up castings. I don't get that, especially when the issue was caused by someone else. If your chimney has been cast correctly and quality controlled then you would have spent maybe 20-30 mins cleaning it up; I've had cast chimneys that have been cast so well they take half that time, even more annoyingly, they've come from kits far cheaper than those cast poorly. To my mind that's 90 minutes of my time wasted resolving someone else's shoddy work, I'd rather spend that time doing something more important.

Cost, you paid for these parts in the first place, if they're not fit then you have to buy more or spend more time/money sorting what you do have.

Being pro does have an impact your time, but in all honesty you're on someone else's clock, it's their money you're wasting, rightly or wrongly I can't abide that. I feel you have a duty of care to ensure the clients money is well spent and he get's value for money, yes it's a shockingly poor business model.

Lets say the hourly rate is £20/hr (that's a fair middle of the ground rate) then you're fettling of the chimney cost the client £40, you can buy a 3rd party one that is cast correctly for what? £10 then half an hour to clean and fit, total cost is £20, half of the cost of cleaning the poorly cast one.

Put another way, you just saved the client £20, better yet you just saved yourself 90 minutes which you can either spend on the model doing something more productive or go down the pub earlier; that works for pro or hobbyist. That's just one chimney, now multiply that by all the other castings in the box.

By unfit I mean something like this and I fully accept I may be in a majority of one.

On the left all the oil lines are merged and riddled with flash and the oil pots malformed with poor lugs and fixing detail.

On the right we have the valve chest covers at the front between the frame extensions (primary viewing eye catching focal point) and the bearing cups for the bogie, the cups are not round and if turned would then be undersized. The covers have a split line right across the faced and deformed rims, the time spent cleaning them up would be better spent starting again and turning new ones up....but why should you, you paid good cash for this, why should you spend your time sorting this out?

If you were forced to use those parts and had to clean them up (cut all the oil lines off, redrill and fit new ones and clean the pots) then you're easily looking at four, maybe six hours work; that's one of those really difficult conversations you end up having with clients.

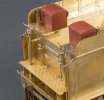

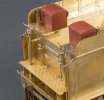

Conversely here's a crop of the tender from the same kit, those handbrake and water scoop up stands were perfect, five minutes to clean up, I opted to remove the handles, drill and fit nickel silver wire as it's more robust that the cast brass and the brass ones were a bit oval in cross section. Same for the intermediate buffers, these are good castings, fit for purpose from workable moulds and acceptable quality control.