Peter Insole

Western Thunderer

Ok, so It's taking a little bit longer than expected, but the bodging fun has been steadily continuing! Of course, it goes without saying that I have made extra work for myself in a few areas, as usual, but at least I have some confidence that the finished article will be a bit more bombproof this time around!

The trouble with this kind of engineering (reverse?) is having to find solutions to awkward problems: There always seems to be something that gets in the way of either holding a piece securely, the drill chuck, or in this case; being able to cleanly draw a file across a surface to clean up!

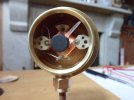

I probably should have taken the apparently easier route of soldering plain studs into the discs, and then attaching nuts from behind... but ended up convincing myself that there was insufficient space down between the "spokes", so opted instead for large headed machine screws - each of which had to be cut only fractionally over length before fitting, in order to reduce the amount of metal that would need to be filed back to flush. All because when I had measured the depth required for the steel centres, I had assumed (yes I know!) that the tyre rims would be the same as the hubs - whereas, it subsequently turned out that the former projected slightly further outwards!

Oh well... I would just have to resign myself to an awful lot of riffling!

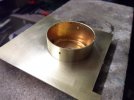

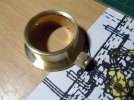

Before tackling that, I wafted some primer on the rear face of the discs to reduce the risk of corrosion between the mild steel and plastic:

I know these are only supposed to be a temporary fix... but such things have a habit of becoming rather more permanent around here, so it seemed to be a sensible precaution!

Cutting threads with cheap, bog standard taps meant that it was almost impossible for me to hide the screw ends... but nothing a swipe of filler and some thick lumpy paint wont cover (?).

I just remembered in time to drill the coned lathe centre points in the axle ends... before getting the jolly paint brushes out!

Apart from a couple more coats of "pretend"; (LYR specification) Japan Black... and the eventual arrival of the essential pair of new "take-up" bearings... (come on please Mr. Mostman Pap!) the leading set are ready for installation.

Pete.

The trouble with this kind of engineering (reverse?) is having to find solutions to awkward problems: There always seems to be something that gets in the way of either holding a piece securely, the drill chuck, or in this case; being able to cleanly draw a file across a surface to clean up!

I probably should have taken the apparently easier route of soldering plain studs into the discs, and then attaching nuts from behind... but ended up convincing myself that there was insufficient space down between the "spokes", so opted instead for large headed machine screws - each of which had to be cut only fractionally over length before fitting, in order to reduce the amount of metal that would need to be filed back to flush. All because when I had measured the depth required for the steel centres, I had assumed (yes I know!) that the tyre rims would be the same as the hubs - whereas, it subsequently turned out that the former projected slightly further outwards!

Oh well... I would just have to resign myself to an awful lot of riffling!

Before tackling that, I wafted some primer on the rear face of the discs to reduce the risk of corrosion between the mild steel and plastic:

I know these are only supposed to be a temporary fix... but such things have a habit of becoming rather more permanent around here, so it seemed to be a sensible precaution!

Cutting threads with cheap, bog standard taps meant that it was almost impossible for me to hide the screw ends... but nothing a swipe of filler and some thick lumpy paint wont cover (?).

I just remembered in time to drill the coned lathe centre points in the axle ends... before getting the jolly paint brushes out!

Apart from a couple more coats of "pretend"; (LYR specification) Japan Black... and the eventual arrival of the essential pair of new "take-up" bearings... (come on please Mr. Mostman Pap!) the leading set are ready for installation.

Pete.

Last edited:

) right down to the axle.

) right down to the axle.