spikey faz

Western Thunderer

Just the sort of finish I'll be aiming for when I finish building my Crosti (or Crusty!).Here's three "not great but may be useful" shots I took of a rebuilt Crosti 92020 at Southall on 5th December 1965. My copyright.

BrianView attachment 158480View attachment 158481View attachment 158482

Mike

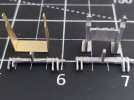

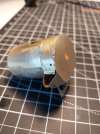

I should have checked as it turns out the etched dimples are not in the right place. Oh , and I think the holes for the ladder might be on the wrong side!

I should have checked as it turns out the etched dimples are not in the right place. Oh , and I think the holes for the ladder might be on the wrong side!