spikey faz

Western Thunderer

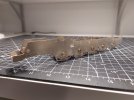

Multiple spring laminations! One of those tasks that looked tedious but once again I found quite relaxing. There is a bit of cleaning up to do on the springs but they are satisfyingly chunky.

The dark staining is where I 'blued' the metal. Just in case I can't get to these areas for painting later on.

Just bluetacked the frames together to get an idea of how it all looks. A bit bigger than a Simplex!

Mike

The dark staining is where I 'blued' the metal. Just in case I can't get to these areas for painting later on.

Just bluetacked the frames together to get an idea of how it all looks. A bit bigger than a Simplex!

Mike