This is my christmas gift to myself. A new project, a bit exotic probably.

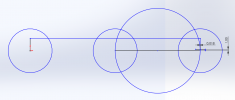

I had a chance to purchase a 7mm kit of the quite exotic Bavarian class Pt2/3, later called class 70. This engine has the quite uniqe design (1B) with two coupled axis close together and a leading axle 4 metres away.

The engine had initially no bogey, only the last axle had side play.

Initially designed in 1909, the engines lasted into the 1960s before they were withdrawn. The idea of these light engines was that the fireman would also serve as a conductor. The engine had a door in its backwall to move to the coaches. The engine was specially designed to pull "light passenger trains" on main lines. In later years, it was ousted to branch lines. Some 50 of them were converted to have a "Bissel"-axle that improved its ability to negotiate tight curves. In fact, they were converted from 1B to 1'B .

I am planning to build the kit to reflect the appearance in the 1930s.

The kit has been desigend in the 1980 by Gerard, Vienna. Mr. Gerard sold his kits in monthly stages, my kit has 12 small leaflets that describe a months work. Most of Mr. Gerards designs were H0-kits, only very few 0-kits were sold. I could get one that was completely untouched. The brass will need a bit of glass fiber brush treatment, but it is of extraordinary quality.

These kits were very special at their time. They had some kind of bad reputation, because the H0-kits were very delicate and had some tiny components. People were saying "these are no kits, these are scaled down prototypes."

One of the most extraordinary components of the kits are the wheels. They are rim isolated with nickel silver tyres and brass cast wheel centres.

But the brass casted parts aren't bad either, considering that they were produced 40 years ago.

I plan to present the progress in line with the kit stages, stay tuned...

Merry Christmas to all of you. This is a great community. I enjoy it very much to be a part of it.

Michael

A lot of 2000 wet and dry removed the worst part of it, but I won't show you a close up of this engine, it is too embarassing. Varnish is my most feared opponent, it can ruin a lot of work in five minutes.

A lot of 2000 wet and dry removed the worst part of it, but I won't show you a close up of this engine, it is too embarassing. Varnish is my most feared opponent, it can ruin a lot of work in five minutes.