Rob Pulham

Western Thunderer

Thanks Dave,Very nice, Rob. Don't forget the water control rod carrying on up to the cab from the universal joint on top of the middle bit of the injector,

The front end of the injector was supported on a bracket that attached to two of the flange bolts holding the large bore exhaust steam pipe. You can see it in the colour photo you posted earlier. Perhaps the component you query is an attempt at that?

Dave.

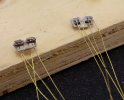

I had meant to add the control rod (admittedly I didn't actually know what it was) but got distracted by trying work out how it mounted. I will add it next.

If the bracket is meant to be the one that you refer to on the photo, the mounting slots in the rear frame etch are in the wrong orientation.... I think that I will be doing my own thing to fit it securely.