James Spooner

Western Thunderer

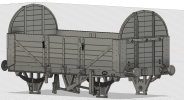

That’s looking very good Will! When I am cleaning up solder, if it is just a mere smear, I find the fibreglass pens very helpful. They seem to be strong enough to rub away the solder whilst too soft to obliterate the etched brass detail.The grande vitesse van is all painted up. I'm not entirely convinced by the colour although the beauty of modelling SECR is nobody can actually decide what the correct colour is anyway!

I've not decided I've I'm going to line it or not yet. Once that's settled I'll make the final push and get it done

View attachment 235409

View attachment 235410

I've been working on my second etched kit this week. It's the aforementioned Roxey mouldings LCDR brake third. This is definitely a step up in difficulty. The instructions aren't nearly as good and some etches don't seem quite right. The duckets for example don't seem to be designed with the curve where it meets the carriage side, instead just having a flat plane. It was easy enough to reshape it into a curve with some trimming and sanding but given how new I am to this game I was a little nervous departing from the instructions.

I also found out the hard way what happens when you hold the soldering iron in one place for too long, hence the little dent in the non-ducket end

The coach seemed to have an infinite number of overlays and door handles which meant just preparing the coach sides took the same amount of time as the whole Grande Vitesse van build. The sides need some more tidying up

If anyone has tips for removing excess solder from the panel lines beyond just scribing it out they'd be much appreciated!

View attachment 235411

View attachment 235412

View attachment 235413

View attachment 235414

I'm very much enjoying this etched brass lark but I can't help but feel the more I do the more daunted I become about the prospect of attempting a loco, especially the high level neilson I've got on the way!

Will

Nigel