You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

7mm On Heather's Workbench - the only one left

- Thread starter Heather Kay

- Start date

-

- Tags

- 0-6-0 2251 class 7mm collett gwr tender loco

Brian Daniels

Western Thunderer

Pictures of 9466 when it visited Didcot on my Flickr if they are of any use 94xx Details

I might get one of these kits as I do have a Finney working inside motion set all attached to a crank axle that should be ok for these I think?

I might get one of these kits as I do have a Finney working inside motion set all attached to a crank axle that should be ok for these I think?

Tender Construction Begins

Heather Kay

Western Thunderer

For now, the loco chassis has been thrown back into the box. The disparity between the instructions and what I have in the pile of parts proved too much for me at the moment. If I want sprung suspension, there's a ton of drilling and tapping to do to the hornguide castings, unless I opt for third party ones. I shall have to commune with the client over that.

So, how about the tender? That should be a bit simpler.

This is the result of a couple of hour's filing etch cusps. The instructions are fit only for the bin, frankly.

The text tells me what to do, but the photos don't help. They show a partly assembled inner frame, but no idea how to get there. How anyone thought this form of instruction would be better than the CAD-derived exploded diagrams beats me.

"Solder pick up scoop onto rear spacer and make up and fit operating gear and stays."

Not one photo shows that assembly, and the provided works drawings are for the tender body only. It's just as well Mr Daniels got some photos - but wait! The scoop has been removed on 3205 in preservation.

I'm off for a sulk.

So, how about the tender? That should be a bit simpler.

This is the result of a couple of hour's filing etch cusps. The instructions are fit only for the bin, frankly.

The text tells me what to do, but the photos don't help. They show a partly assembled inner frame, but no idea how to get there. How anyone thought this form of instruction would be better than the CAD-derived exploded diagrams beats me.

"Solder pick up scoop onto rear spacer and make up and fit operating gear and stays."

Not one photo shows that assembly, and the provided works drawings are for the tender body only. It's just as well Mr Daniels got some photos - but wait! The scoop has been removed on 3205 in preservation.

I'm off for a sulk.

Heather Kay

Western Thunderer

I think it's a genuine JLTRT. All the etched are branded so.

I just noticed the "instructions" are actually referred to as an "assembly guide". Says it all, really. I shall have to have further words, because this can't go on.

I just noticed the "instructions" are actually referred to as an "assembly guide". Says it all, really. I shall have to have further words, because this can't go on.

Pencarrow

Western Thunderer

It strikes me we are always told to have good photos of our chosen prototypes when we build, but more often than not they only serve to show what's wrong in the kit!

On my delightful 1366 build I've found photos to be an absolute godsend and destroyer of hope/sanity in equal measures.

Other than a few 'snags' with parts that didn't fit, I started off the building without changing much and building it as the manufacturer intended. I then started to look at photos to work out where some of the bits went and to check on variations for 1368.

The more I looked the more I found wrong. Oh dear, so much for 'modern' kits being better! Still, the end result will hopefully be better for it. I do wonder sometimes though (normally when I've spotted another issue) whether there's something to be said for proceeding in blissful ignorance!

No, scrap that idea, I'd be upset when somebody pointed out all the errors on my finished model. Got that t-shirt. ;-p

Stoke5D

Western Thunderer

I think it's a genuine JLTRT. All the etched are branded so.

I just noticed the "instructions" are actually referred to as an "assembly guide". Says it all, really. I shall have to have further words, because this can't go on.

I've got a few JLTRT kits but only Diesel and Wagons/Vans, no Steam. The Diesels are mostly good as noted in this forum in several example builds but the freight stuff is disappointing, with too much whitemetal where it doesn't suit and a lot of generic (ie. inaccurate) parts, although the resin bodies are impressive.

You are doing a doing a sterling job here but these issues aren't a great advert for the Steam side of the range...

Andrew

Tender Chassis

Heather Kay

Western Thunderer

Just another working day. Weekends are very much optional here!

After having done my housework, I settled at the workbench to see if I could work out how to build the tender without instructions! Happily, OzzyO's build over on RMW held some vital clues, so I rummaged in the spares cabinet for the right kind of bearings for a start. Having found suitable ones in the stash, I felt I could actually attempt to get the inner frame near to rolling today.

Well, not too bad. A couple of errors in the kit, pointed out on t'other place, such as the water scoop mechanism on the driver's side. The knock-on here is the brake weighshaft brackets are etched the wrong way round. Ozzy's solution was to reverse the part. I decided to mark out and drill a new hole in the right place, then plug the errant one later. That way the etched part fitted the frame as the designer intended. It should be note the chassis is designed to have a rigid rear axle, with the remaining pair sprung. It would be possible to engineer a compensated system, but I'm happy to roll with things as they are.

It's looking more and more likely fitting any form of sound and digital control to this model will be all but impossible. The tender body is hollow, but isn't accessible unless some serious surgery is made to the chassis parts. There isn't really anywhere sensible on the loco, with the tiny area around the front axle being about the only spare cavity available. I may have to discuss this with various parties and see what options are open to us.

Time to give this build a rest and get on with something else for a week.

After having done my housework, I settled at the workbench to see if I could work out how to build the tender without instructions! Happily, OzzyO's build over on RMW held some vital clues, so I rummaged in the spares cabinet for the right kind of bearings for a start. Having found suitable ones in the stash, I felt I could actually attempt to get the inner frame near to rolling today.

Well, not too bad. A couple of errors in the kit, pointed out on t'other place, such as the water scoop mechanism on the driver's side. The knock-on here is the brake weighshaft brackets are etched the wrong way round. Ozzy's solution was to reverse the part. I decided to mark out and drill a new hole in the right place, then plug the errant one later. That way the etched part fitted the frame as the designer intended. It should be note the chassis is designed to have a rigid rear axle, with the remaining pair sprung. It would be possible to engineer a compensated system, but I'm happy to roll with things as they are.

It's looking more and more likely fitting any form of sound and digital control to this model will be all but impossible. The tender body is hollow, but isn't accessible unless some serious surgery is made to the chassis parts. There isn't really anywhere sensible on the loco, with the tiny area around the front axle being about the only spare cavity available. I may have to discuss this with various parties and see what options are open to us.

Time to give this build a rest and get on with something else for a week.

Dikitriki

Flying Squad

Hi Heather,

You will have no problem fitting DCC and sound. You don't require a huge chip with an efficient motor, and a cube speaker will fit under the footplate at the front behind the buffer beam. I can provide pics of my L&Y 0-6-0 which has such an arrangement if you are interested.

Richard

You will have no problem fitting DCC and sound. You don't require a huge chip with an efficient motor, and a cube speaker will fit under the footplate at the front behind the buffer beam. I can provide pics of my L&Y 0-6-0 which has such an arrangement if you are interested.

Richard

Heather Kay

Western Thunderer

Thanks Richard.

I think I'll still need to cut a hole in the tender floor. There's a lot of stuff to fit the frames, which may get in the way of the electronics. I shall look at a way of attaching the resin bodywork to the floor without glue.

I think I'll still need to cut a hole in the tender floor. There's a lot of stuff to fit the frames, which may get in the way of the electronics. I shall look at a way of attaching the resin bodywork to the floor without glue.

Heather Kay

Western Thunderer

I'm probably not being very clear. Being a technophobe, I am not fitting the electronics personally. This means I'm having to think in rather abstract ways about what might fit where later on.

The 3500 gallon tender is quite a busy animal under the frames. There's the brake rigging, with a vac cylinder and reservoir, plus the water scoop and attendant gubbins. My worry is there will be precious few spaces left to fit the DCC PCB. What I shall do is have a chat with Tim to see if he might be able to provide sizes of things electronical.

The 3500 gallon tender is quite a busy animal under the frames. There's the brake rigging, with a vac cylinder and reservoir, plus the water scoop and attendant gubbins. My worry is there will be precious few spaces left to fit the DCC PCB. What I shall do is have a chat with Tim to see if he might be able to provide sizes of things electronical.

Tender Scoops and Other Things

Heather Kay

Western Thunderer

Right, having got so far with one tender and been baulked I turned attention to this beastie once more.

I managed to fit the water scoop, despite the castings needing a fair whack of tidying up. Next was the vacuum reservoir…

Only there isn't one in the box. Nor is it listed on the parts manifest. Laurie at JLTRT must be getting a bit fed up with my emails today!

Time to consider surgery for internal access.

You can see some wiggly lines scribbled on the main floor. Well, they mark out an area that could potentially be cut out to allow access to inside the tender body once the chassis is out of the way. While I was about it, I considered if it might be possible to alter the resin tender body such that the rear platform could be lifted out for access purposes. I might see if a spare body casting can be sent over.

So, despite getting some good hours on two builds, today has been a tale of two steps forward and half a step back.

I managed to fit the water scoop, despite the castings needing a fair whack of tidying up. Next was the vacuum reservoir…

Only there isn't one in the box. Nor is it listed on the parts manifest. Laurie at JLTRT must be getting a bit fed up with my emails today!

Time to consider surgery for internal access.

You can see some wiggly lines scribbled on the main floor. Well, they mark out an area that could potentially be cut out to allow access to inside the tender body once the chassis is out of the way. While I was about it, I considered if it might be possible to alter the resin tender body such that the rear platform could be lifted out for access purposes. I might see if a spare body casting can be sent over.

So, despite getting some good hours on two builds, today has been a tale of two steps forward and half a step back.

today has been a tale of two steps forward and half a step back.

Isn't that the story of a lot of kits today Heather? It's hard to find a complete one that actually goes together now...

Tender Frames and Bodywork

Heather Kay

Western Thunderer

I've been plodding on with the tender bodywork today.

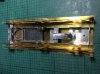

Here's a better view of the chassis. I've got to fit the axleboxes, and then there's a ton of fiddly stuff like brakes and pipework.

It's not a lot of fun trying to build something when the instructions are virtually non-existent. It took me a while to figure out how the side frames fitted, how the steps were formed, and where the reinforcing brackets went. It wasn't until I was about to fit the front drag beam that I realised the front steps were cranked inwards!

(I know. I should have noticed that in the photos, but that's not the point.)

It's not obvious what some of the etched parts are or where they fit. I think I've fitted the right parts as braces between the frames and steps. There's something nagging at the back of my mind about the water scoop operating mechanism that may or may not fit inside or outside the framing. I do remember it's on the driver's side, but I expect some swearing to occur when it comes to fitting it! In any case, there are several etched parts for which I can find no purpose at present.

The rear buffer plank went together well. It paid to take my time, ensuring squareness and fit was good.

This is where I am at present, with the body casting posed on top. Much of the hot soldering has been done, so I can begin to think about the whitemetal castings for the springs and axleboxes.

Now I come to look at it, I'm quite pleased with progress. I usually feel I take far too long to get anywhere, but things seem to be moving along at a reasonable pace. I suspect it'll all slow down when I get to the detailing.

Here's a better view of the chassis. I've got to fit the axleboxes, and then there's a ton of fiddly stuff like brakes and pipework.

It's not a lot of fun trying to build something when the instructions are virtually non-existent. It took me a while to figure out how the side frames fitted, how the steps were formed, and where the reinforcing brackets went. It wasn't until I was about to fit the front drag beam that I realised the front steps were cranked inwards!

(I know. I should have noticed that in the photos, but that's not the point.)

It's not obvious what some of the etched parts are or where they fit. I think I've fitted the right parts as braces between the frames and steps. There's something nagging at the back of my mind about the water scoop operating mechanism that may or may not fit inside or outside the framing. I do remember it's on the driver's side, but I expect some swearing to occur when it comes to fitting it! In any case, there are several etched parts for which I can find no purpose at present.

The rear buffer plank went together well. It paid to take my time, ensuring squareness and fit was good.

This is where I am at present, with the body casting posed on top. Much of the hot soldering has been done, so I can begin to think about the whitemetal castings for the springs and axleboxes.

Now I come to look at it, I'm quite pleased with progress. I usually feel I take far too long to get anywhere, but things seem to be moving along at a reasonable pace. I suspect it'll all slow down when I get to the detailing.

Brian Daniels

Western Thunderer

I have just added another 38 pictures to my 2251 Flickr site 2251 Details Hope they are of use.

Tender Floor, aka Swiss Cheese

Heather Kay

Western Thunderer

Some excellent additions to the set there Mr D. Thank you for sharing!

I burned some midnight oil yesterday. It was one of those days where things began to go quite well, and I gave Mrs Mojo the time to complete the task in hand while she was in the mood.

Let's just say the Dremel and slitting disc saw quite a lot of action. The machine got quite warm, and the disc lost a lot of diameter. Why? Read on!

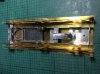

When a kit is designed but no adjustment allowed for over-scale flanges, some surgery is required to clear things. To be fair, it does actually mention this fact in the "instructions". The variation in the slot shapes is because the rear axle is fixed and only needs side-to-side clearance, while the other two are sprung and need up and down clearance as well.

Fitting the tender floor and pushing the model along while pressing down on it revealed some clearance will also be required on the floor itself. I've started by using the whizzydisc to create spaces, but it may just end up with more 'oles.

Oh, yes, I've got the tender on wheels. Did I forget to mention?

On with the day!

I burned some midnight oil yesterday. It was one of those days where things began to go quite well, and I gave Mrs Mojo the time to complete the task in hand while she was in the mood.

Let's just say the Dremel and slitting disc saw quite a lot of action. The machine got quite warm, and the disc lost a lot of diameter. Why? Read on!

When a kit is designed but no adjustment allowed for over-scale flanges, some surgery is required to clear things. To be fair, it does actually mention this fact in the "instructions". The variation in the slot shapes is because the rear axle is fixed and only needs side-to-side clearance, while the other two are sprung and need up and down clearance as well.

Fitting the tender floor and pushing the model along while pressing down on it revealed some clearance will also be required on the floor itself. I've started by using the whizzydisc to create spaces, but it may just end up with more 'oles.

Oh, yes, I've got the tender on wheels. Did I forget to mention?

On with the day!

Heather Kay

Western Thunderer

I don't know, Graham. If they use standard Slater's axles, perhaps we might engineer a trial at Mark on Saturday?

Personally, as the area is hidden, I would probably cut a slot anyway, just in case.

Personally, as the area is hidden, I would probably cut a slot anyway, just in case.