Hi Frazer

You may be right. I'd hoped that the JLTRT bogie would be a better representation than the awful cast white metal parts in the old MSL Hobbies. In most senses it is, but the end sections of the bogies are very different. The original Ivatt bogies have the sand boxes sitting in fabricated pockets on all four corners of the bogie. These had to be machined and reshaped to better represent the EM2 versions. The EM2 bogie sides don't have a raise section over the centre axlebox and there are differences in the axleboxes themselves. The bogie (coil) springs are enclosed on the EM2 version as well. The donor of the resin bogie parts didn't include any castings, so I don't have the leaf springs or spring planks and swivel links, but maybe they're not in the 10000 kit. The braking system of the EM2s are completely different from that fitted to the originals, so it doesn't matter that I don't have them. None of the commercially available versions of the bogie (PRMRP do a version too) give the impression of a bogie fabricated from plate sections, although I did drill some holes in the JLTRT resin ones to try and give the hollow look.

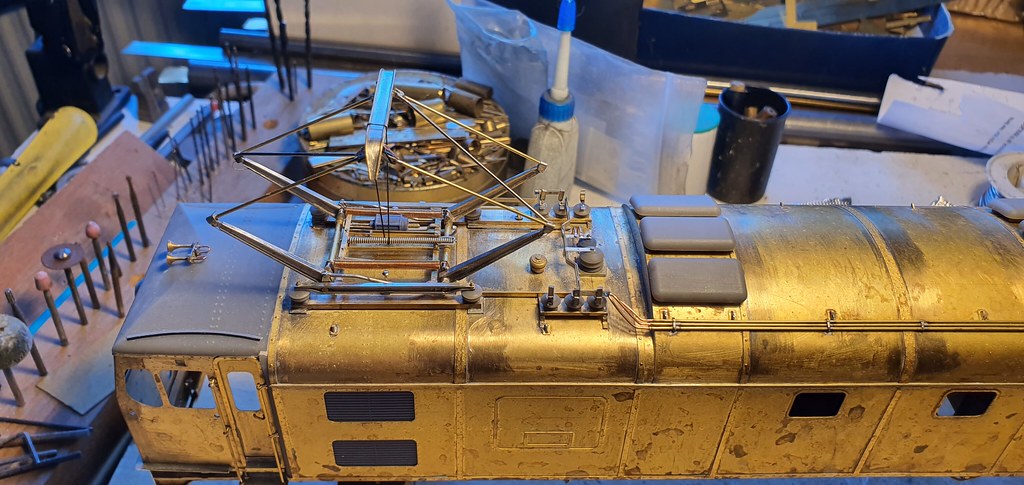

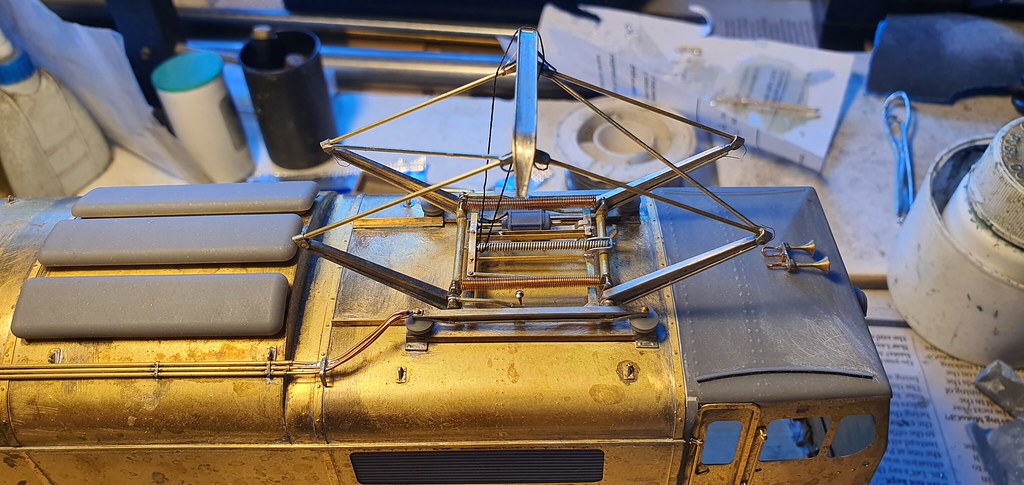

The JLTRT bogies have an inner chassis for the wheels and motor so you don't get that see-through appearence, but I'll take that because they're the best available and good in lots of other ways. The pantos for this build took 3 weeks to fabricate and I would guess that fabbed bogies would take longer, and the cost would begin to run away. If I were making them on an infinite budget I'd go for it and use a couple of ABC traction motor gearboxes on one of the axles.

I have never built owt with a Delrin chain and was intrigued by them. They work really well, and if the infinite budget applied I'd be faffing about with a chain tensioner design after the style of the ones in a (Meriden) Triumph Bonneville primary or an Alfa Romeo Duetto cam chain. It'd be a challenge to find a tensioner that worked with the chain spinning in both directions. Now there's a rabbit hole.........

Nick