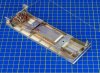

A new week and a new project, not quite, time to spend some quality time back with the MR compound kit. The final (hopefully) tender test etches turned up a few weeks back; so it's a case of building it, photographing it and knocking up some words for the blurb.

The metal work so far is all fine, so it was time to flex some electrons and see what the printer turfed out. I'm not sure....and I haven't checked extensively.....but I don't think there are any 3rd party castings to suit this type of axle box and spring hangers so it was 3D or nothing really.

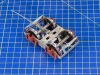

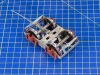

The two main differences are the lower shackle brackets and the twin rod retention bars, very much like the Cartazzi trucks on Gresley engines, Thompson and Peppercorn too if I recall correctly. The rods are not fitted yet, I'll fabricate some up later on, some brass rod and small nuts will do the trick.

MR and then LMS moved on around the same time to the then to become standard flat bar bolted to the frames, some bogie tenders fitted to other engines employed flat bars, but these are twin rod versions.

The axle box is currently only held on by the lower pins which are soldered to the frames, this allows them to be pulled off and the lining completed behind the springs. The wheels are also lined, so need to be pulled out as well; to accommodate that, the axle box rear is hollowed out to accept the bearing and wheel set removal. It does leave a hole in the bottom, but that's a small price to pay.

The upper pins are, quite frankly, an enthusiasm feature. They can be printed, but even the Form has trouble clearing and forming the pin between the shackle faces. The other downside is that the rear is the sacrificial face and any pin printed on the rear gets sanded off. So despite being a bit of a pain to cut and fit, the individual pins do look much better and add a nice detail.

The brake shoes are simple monkey see monkey do affairs, although getting just the right orientation to minimise artifacts has proved a little more time consuming than I envisaged/wanted, but they're nearly there; these only needed a slight waft with the fibre brush to clean up. Conversely the axle box and spring assembles knocked out the park very early on in that respect.

The brake pull rods are held in place with small pins through the beams and the lower section of the bolster with equalising links all comes out as well as one unit, so it breaks down nicely for paint.

I may rework the springs a little in later (final) renditions, primarily around the upper pin and shackle area, currently the Y shaped link blends in with the spring at the end, I need to pull the spring face back toward the centre by about 0.1 - 0.15 to define the two as separate items so to speak.

The Chassis and bogies are okay as they've not been though yet.

The Chassis and bogies are okay as they've not been though yet.

it's late in the end of a long day

it's late in the end of a long day

All good practice for when I get to my SAR Garratts

All good practice for when I get to my SAR Garratts