Back to the loco. Most electrically powered locos, as far as I know, are built using a separate chassis and body, the body removing to get at the works. That's not going to work here because of the way the leading wheel spring is attached. The hangers are bolted to the frames to take the load, but the front hanger has to pierce the smokebox wrapper.

That means if you bolt the hangers to the frames, you can't get the smokebox off, but with the smokebox and boiler in place it is all but impossible to remove the spring. Incidentaly, on the real thing lead sheet was forced into the space between the hanger and the wrapper to preserve the smokebox vacuum. It all sounds like a bit of a bodge. Couldn't they come up with a better idea? Clearly, DFMA (Design for Manufacture and Assembly) hadn't been invented in Victorian times.

My answer is to attach the smokebox permanently to the frames. The boiler is part of the body assembly, and bayonets into the back of the smokebox. To remove the body, release the screws which will be under the cab, slide the body backwards about a millimetre, and lift it off vertically. It will work because there are only two external pipes connecting the boiler and the smokebox and it's easy enough to release them for dismantling.

The smokebox skeleton is a straight forward bit of sawing, filing, and turning.

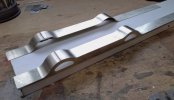

Thw wrapper has two rows of rivets at front and rear. I decided to press them rather than add them separately and solder them, partly because I couldn't find any rivets of the right size, but mainly because I didn't fancy drilling so many tiny holes.

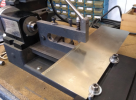

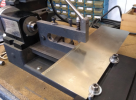

When I made my rivetting tool, many years ago, I designed it so that it could be clamped to the bed of my Sherline lathe. The work is clamped to the cross slide and moving the saddle and cross slide gives nice uniform rows of rivets in both directions. Here is the first row

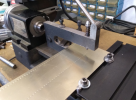

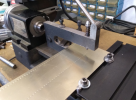

and here is the second row, positioned by cranking the x-axis the correct amount and maintaining the same spacing on the cross slide.

I prefer doing it that way than relying on the anvil diameter to space the rivets. It works better for me but I know that the late, great Beeson and Reynalds both used the anvil edges, and who am I to argue?

Nick