Giles

Western Thunderer

HA..... I haven't got over the last one yet....!!!!!

I've printed up the correct centres for the pony truck. Before cleaning up

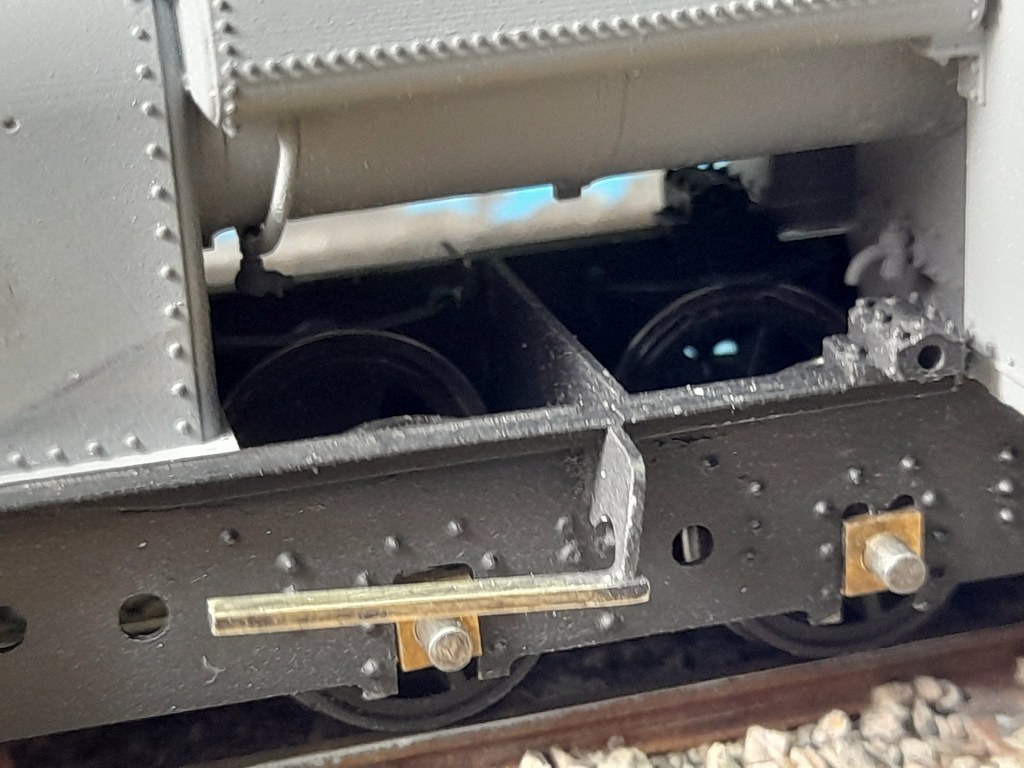

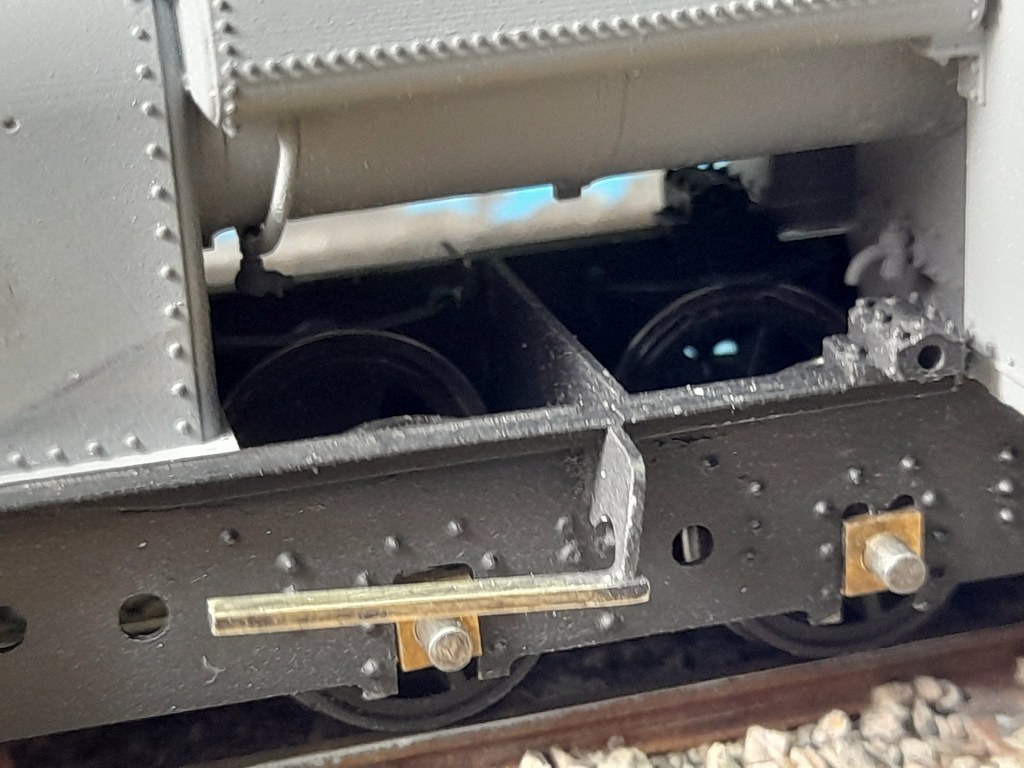

I've used the pony truck pivot stretcher as a foundation for the motor mount (radio control 8mm gearmotor). Build up with epoxy putty, and when dry, the motor is held in with two small blobs of epoxy glue.

The gearmotor sits just below the cab floor. Also visible is the ball for the pony truck.

From the side, you can see that the gearmotor isn't very visible.

The view between the frames. Obviously a conventional drive will be more obtrusive than this.

Lastly, the Cranks ready for fitting, having had holes whilst mounted in the printed collets seen earlier.

I've printed up the correct centres for the pony truck. Before cleaning up

I've used the pony truck pivot stretcher as a foundation for the motor mount (radio control 8mm gearmotor). Build up with epoxy putty, and when dry, the motor is held in with two small blobs of epoxy glue.

The gearmotor sits just below the cab floor. Also visible is the ball for the pony truck.

From the side, you can see that the gearmotor isn't very visible.

The view between the frames. Obviously a conventional drive will be more obtrusive than this.

Lastly, the Cranks ready for fitting, having had holes whilst mounted in the printed collets seen earlier.