7mmMick

Western Thunderer

I'm now deep into the A2/3 build, which seems to be one step forward two back at the moment. For some welcome relief i've picked up a commission build of the above. The build comprises of a Finney7 Hall and Collett 4000G tender. It will be DCC fitted and have working inside motion. I won't be doing a blow by blow account per say as @SimonT has done a great job elsewhere but i'll be posting little bits with a few tips to help out future builds where I can.

As always i'm starting with the tender as that usually helps motivate me to crack on with the loco build and it's always nice to have the tender completed on the shelf over the bench, waiting for it's first journey!

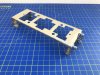

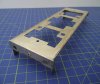

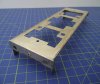

The tender kit is based on the usual MF compensation and is built in a number of sub assemblies. The main frames, footplate and tender tank. I'm still waiting for wheels so the upper works have seen the most attention so far. First the beginnings of the main frames, as it stands the wheels will be permanently trapped, which I don't like the idea of so I have a cunning plan! More on that later though as I have to prove concept first;

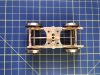

You'll see here that the front brake pivot rod is missing. The instructions say to fit the rocking beam first, I wouldn't as it makes the front brake rod harder to fit. If you fit that first, fix and part off, the fit the rocking beam life would be much easier. Next the footplate, this is a series of laminations and although it doesn't look like much there's quite a bit of work to get here;

If you're fitting the MF tapered Collett buffers don't fit the rear buffer beam before drilling out 3/16. The buffers holes are etched way undersized and if you fit it then try and open them out you're causing yourself some real pain;

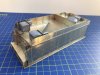

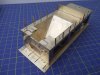

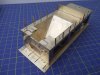

Buffer beam drilled for buffer housings. Next is the tank and this is where the main effort has been concentrated. The construction is again classic MF, a box section around which a large overlay for the sides and back with all rivet detail is fitted. There is also a large overlay for the tank top, which has lots of rivets to press. Don't be tempted to use the GW rivet tool here as the rivets are just too small. I have a basic rivet punch, which i've had from my 4mm days and that seemed ideal. The anvil is obviously much smaller;

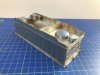

And finally i've started work on the main wrapper, which is very large! The flare was not fun to form but it's getting there. Still more work to do here before final fitting, check, bend, check again, a little more, check again..............

Once the wrapper is fitted it's onto the coal space sides, a few more overlays and then final detailing. As it stands it's only really a small bag of etched bits and castings to fit, the main construction is 2/3 there. An enjoyable couple of days so far.

Oh and not to forget, i've cropped one of my own photos to cut my ugly mug out but here's the big reveal explaining the 'aka' in the title

Cheers

Mick

As always i'm starting with the tender as that usually helps motivate me to crack on with the loco build and it's always nice to have the tender completed on the shelf over the bench, waiting for it's first journey!

The tender kit is based on the usual MF compensation and is built in a number of sub assemblies. The main frames, footplate and tender tank. I'm still waiting for wheels so the upper works have seen the most attention so far. First the beginnings of the main frames, as it stands the wheels will be permanently trapped, which I don't like the idea of so I have a cunning plan! More on that later though as I have to prove concept first;

You'll see here that the front brake pivot rod is missing. The instructions say to fit the rocking beam first, I wouldn't as it makes the front brake rod harder to fit. If you fit that first, fix and part off, the fit the rocking beam life would be much easier. Next the footplate, this is a series of laminations and although it doesn't look like much there's quite a bit of work to get here;

If you're fitting the MF tapered Collett buffers don't fit the rear buffer beam before drilling out 3/16. The buffers holes are etched way undersized and if you fit it then try and open them out you're causing yourself some real pain;

Buffer beam drilled for buffer housings. Next is the tank and this is where the main effort has been concentrated. The construction is again classic MF, a box section around which a large overlay for the sides and back with all rivet detail is fitted. There is also a large overlay for the tank top, which has lots of rivets to press. Don't be tempted to use the GW rivet tool here as the rivets are just too small. I have a basic rivet punch, which i've had from my 4mm days and that seemed ideal. The anvil is obviously much smaller;

And finally i've started work on the main wrapper, which is very large! The flare was not fun to form but it's getting there. Still more work to do here before final fitting, check, bend, check again, a little more, check again..............

Once the wrapper is fitted it's onto the coal space sides, a few more overlays and then final detailing. As it stands it's only really a small bag of etched bits and castings to fit, the main construction is 2/3 there. An enjoyable couple of days so far.

Oh and not to forget, i've cropped one of my own photos to cut my ugly mug out but here's the big reveal explaining the 'aka' in the title

Cheers

Mick

The rivets on the coal space and tank top are very small.

The rivets on the coal space and tank top are very small.