mickoo

Western Thunderer

Just a small update, course work, revision and exams have kept me away from the bench for a few days.

The wheels arrived today, spot the mistake

Fortunately I also ordered the correct 120° axles, not that you can see them, but I know they are there.

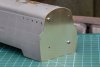

They do make a difference to the visuals, need to tweak the ride height and then the brakes to make it all look a tad better, also got a chance to fit the smoke box footplate wing plates and atomisers as well as the AWS battery box cover, still quite a bit of solder to clean up here and there.

The pipework for the atomiser is a new definition of fiddly to me but the more you do, the better you get. The drivers side is done and I'll take a big breath and fresh start one early morning over the weekend to do the firemans side.

Looking at photos I wasn't comfortable with the moulded atomiser feed pipes on the smokebox face and they were not in exactly the right place, close enough if your going to leave them in place, but if being replaced they can be moved the small fraction to align with the inspection cover just so.

In addition, trying to get the copper feed pipes from the atomiser to line up with the plastic ones looked next to impossible, so off they came and whole new runs added in copper wire. In addition I drilled the holes in the footplate to let the feed pipes drop through as per the real engine, the pipes are then folded up underneath and blind soldered, which adds extra strength but not near the holes, it is important to keep them clear so the pipe looks like it is passing through the sheet metal.

I still need to add the retaining straps but already the visuals of real round pipes over the moulded ones is worth the effort, and in all honesty, probably easier in the long run than trying to get the very short sections needed to line up with the plastic ones. Later in life 110 only had one strap each side so I'd have needed to trim one of the moulded straps off anyway.

The wing plates should have a batten along the top edge to bolt to the deflectors, it can't be part of the plate as that's half etched for the rivets on the outside, but I have an idea to use some of the edges off one of the spare cabs to form a clip along the base of the smoke deflector, the cab edges have a half etch rebate along them, this rebate will fit over the wing plate, add strength, ensure is all lines up neat and square and create the visuals for the batten.

Next up the AWS battery box and coupling guard and then some more panels on the roof as well as the fairing behind the chimney fitted to many of the engines.

MD

The wheels arrived today, spot the mistake

Fortunately I also ordered the correct 120° axles, not that you can see them, but I know they are there.

They do make a difference to the visuals, need to tweak the ride height and then the brakes to make it all look a tad better, also got a chance to fit the smoke box footplate wing plates and atomisers as well as the AWS battery box cover, still quite a bit of solder to clean up here and there.

The pipework for the atomiser is a new definition of fiddly to me but the more you do, the better you get. The drivers side is done and I'll take a big breath and fresh start one early morning over the weekend to do the firemans side.

Looking at photos I wasn't comfortable with the moulded atomiser feed pipes on the smokebox face and they were not in exactly the right place, close enough if your going to leave them in place, but if being replaced they can be moved the small fraction to align with the inspection cover just so.

In addition, trying to get the copper feed pipes from the atomiser to line up with the plastic ones looked next to impossible, so off they came and whole new runs added in copper wire. In addition I drilled the holes in the footplate to let the feed pipes drop through as per the real engine, the pipes are then folded up underneath and blind soldered, which adds extra strength but not near the holes, it is important to keep them clear so the pipe looks like it is passing through the sheet metal.

I still need to add the retaining straps but already the visuals of real round pipes over the moulded ones is worth the effort, and in all honesty, probably easier in the long run than trying to get the very short sections needed to line up with the plastic ones. Later in life 110 only had one strap each side so I'd have needed to trim one of the moulded straps off anyway.

The wing plates should have a batten along the top edge to bolt to the deflectors, it can't be part of the plate as that's half etched for the rivets on the outside, but I have an idea to use some of the edges off one of the spare cabs to form a clip along the base of the smoke deflector, the cab edges have a half etch rebate along them, this rebate will fit over the wing plate, add strength, ensure is all lines up neat and square and create the visuals for the batten.

Next up the AWS battery box and coupling guard and then some more panels on the roof as well as the fairing behind the chimney fitted to many of the engines.

MD

Up until now I'd been using my Britannia spoked wheels to set things up.

Up until now I'd been using my Britannia spoked wheels to set things up.