Peter Insole

Western Thunderer

I couldn't start applying the top coats of paint on the saddle tank until the filler neck, with the problem of a top moulding was completed.

Although the pictures in the previous post show the fitting already part built, there was an overlap in posting the story.

As mentioned before, there are no known rivet details for the tank top, so I have simply set them on the filler flange at the same spacing as the sides and ends.

It took a while to find something suitable to act as a former for the laminated neck, but once again, Mrs, I. came to the rescue with the perfect solution!

The parallel sides of a wee little marmalade jar were just the right depth, and for the first two layers of 0.4mm ply at least, the external diameter was spot on. When set firm enough to handle, it was glued and pressed firmly into the hole, with the jar still inside to ensure no distortion until it cured.

With the jar removed, and the cable ties retained, a third layer was glued to the inside to form the desired thickness.

After allowing it to fully cure and then cleaning up, further progress stalled while I considered the best way to make up a half-round lip. I was not very keen to order anything online, with the prospect of ending up with loads of spare material after cutting the very short length required. The promised trip with Rich to our local model shop provided a potential answer: Two sizes of fairly short strips in what looks and feels more like ABS than styrene of roughly the right proportions were acquired for the princely sum of 80p each.

Not quite problem solved though, as it proved a right old faff to curve it down to the 44mm diameter!

Ironically, there was not enough on the strip for a second try, so I had to put up with the odd twists, deformations and ragged edges that resulted from the struggle caused by poorly controlled heat!

Filler would suffice, and hopefully hide the multitude of errors ?!

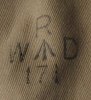

Then it was time at last for that first coat of lovely, pong everyone out of the house, gloss enamel...

Gosh, that stuff really is shouty and shiny isn't it ?!

Not bad for a first coat. After cutting and recoating at least another four times, which will take a while to do it properly, the surface should then be ready for lining out ?!

Pete.

Although the pictures in the previous post show the fitting already part built, there was an overlap in posting the story.

As mentioned before, there are no known rivet details for the tank top, so I have simply set them on the filler flange at the same spacing as the sides and ends.

It took a while to find something suitable to act as a former for the laminated neck, but once again, Mrs, I. came to the rescue with the perfect solution!

The parallel sides of a wee little marmalade jar were just the right depth, and for the first two layers of 0.4mm ply at least, the external diameter was spot on. When set firm enough to handle, it was glued and pressed firmly into the hole, with the jar still inside to ensure no distortion until it cured.

With the jar removed, and the cable ties retained, a third layer was glued to the inside to form the desired thickness.

After allowing it to fully cure and then cleaning up, further progress stalled while I considered the best way to make up a half-round lip. I was not very keen to order anything online, with the prospect of ending up with loads of spare material after cutting the very short length required. The promised trip with Rich to our local model shop provided a potential answer: Two sizes of fairly short strips in what looks and feels more like ABS than styrene of roughly the right proportions were acquired for the princely sum of 80p each.

Not quite problem solved though, as it proved a right old faff to curve it down to the 44mm diameter!

Ironically, there was not enough on the strip for a second try, so I had to put up with the odd twists, deformations and ragged edges that resulted from the struggle caused by poorly controlled heat!

Filler would suffice, and hopefully hide the multitude of errors ?!

Then it was time at last for that first coat of lovely, pong everyone out of the house, gloss enamel...

Gosh, that stuff really is shouty and shiny isn't it ?!

Not bad for a first coat. After cutting and recoating at least another four times, which will take a while to do it properly, the surface should then be ready for lining out ?!

Pete.

Last edited: