Tim Watson

Western Thunderer

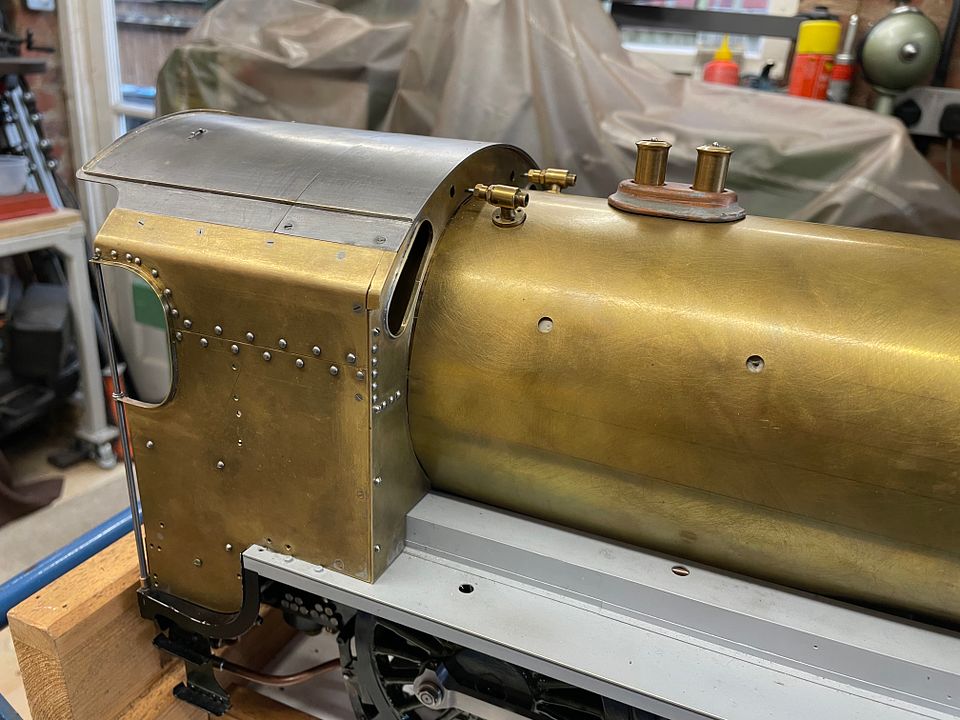

Inside every lump of metal there is a shape trying to come out - actually two in this case.

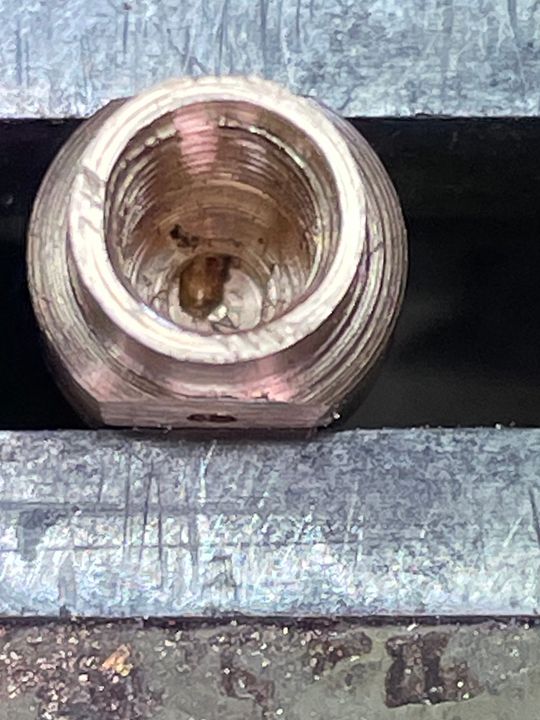

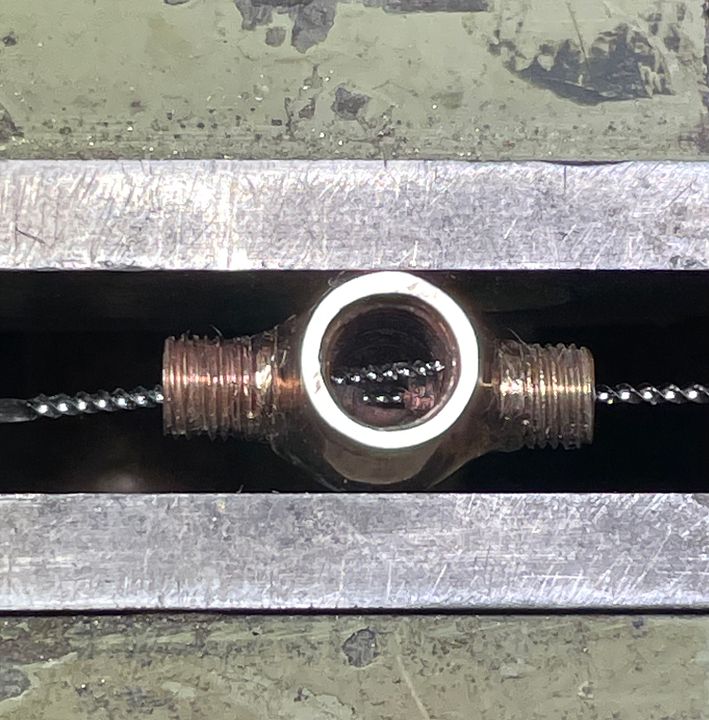

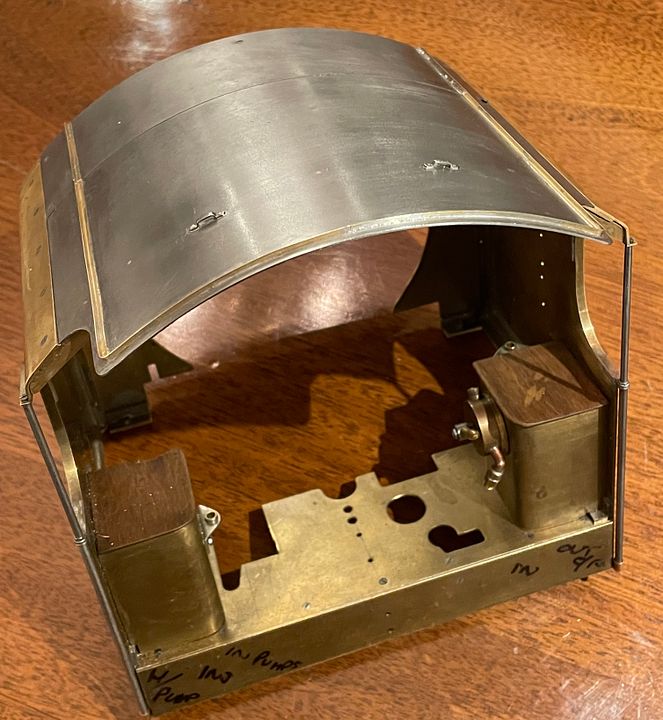

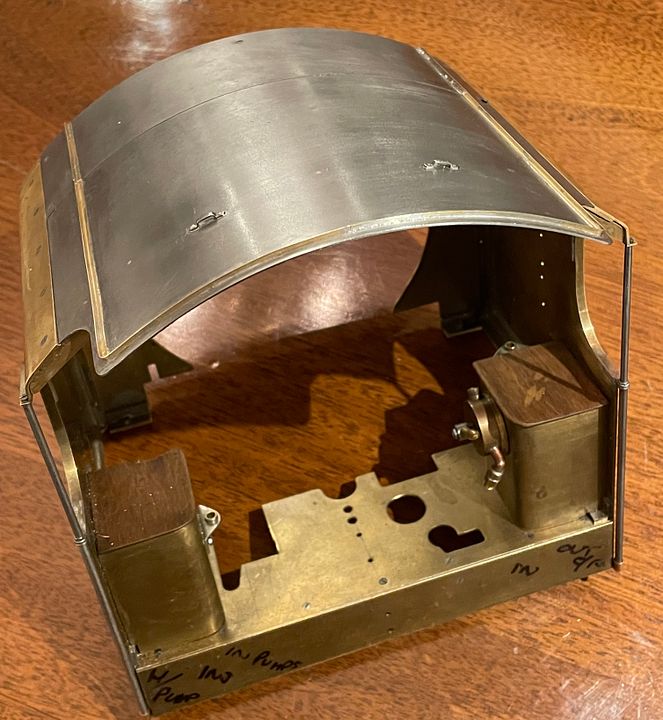

The cab roof handles would probably have helped positioning when the rear was removed for maintenance purposes ( on the prototype).

The metal strip was bent to shape, drilled 0.8mm x 4 and then sliced into two handles. These were tapped 14BA and held in place with bolts whilst soldering.

That’s the roof done.

Tim

The cab roof handles would probably have helped positioning when the rear was removed for maintenance purposes ( on the prototype).

The metal strip was bent to shape, drilled 0.8mm x 4 and then sliced into two handles. These were tapped 14BA and held in place with bolts whilst soldering.

That’s the roof done.

Tim