Hello Michael,

I've also got the cover glasses on order. But the problem with the cover glasses is the size about the largest that I saw were 24 X 24mm, not quit big enough for a Mk1 window and definitely not big enough for a Mk2 window. As the real Mk1 window were in five panes of glass with the bottom pane being set at one angle and the top four at another angle I'm going to see if I can get the affect on the model. Now for a question, were the window in a BG the same?

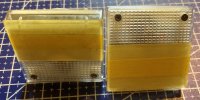

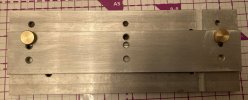

Onto the B4 bogies with a coat of paint on them.

View attachment 186251

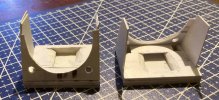

You can see what I've done to add some strength to the top beam. it was getting a length of 1mm N/S in the channel and filling it with super glue jell. Lets see how it works. I've got some more on order but I've got a better idea for them.

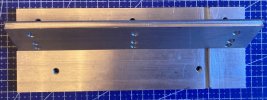

View attachment 186253

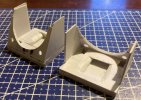

Under coat on the springs and axle box covers.

View attachment 186256

And top coat on.

View attachment 186258

The ETH gear that I'll be using from PRMRP products.

View attachment 186260

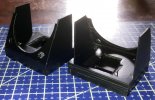

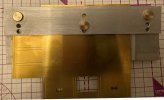

Now onto one of the coaches a JLTRT Mk1 CK. Not a lot to out of the ordinary yet. Apart from using two vee hangers, the inside one should get cut back to the angle trussing.

View attachment 186261

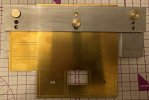

Buffers in place and the channel to clear the spring for the draw gear milled out, I'm going to use the Ellis Clarke drop head buckeye couplings on this coach.

View attachment 186262

You can just make out the pins that I've used to help add some strength to the joint between the trussing and the floor pan. After doing a few JLTRT coaches it dawned on me that the small bit at the ends of the trussing should be folded the wrong way so you get what looks like a channel.

View attachment 186263

While I was on the bay of E I decided to have a look for a set of Maun parallel jaw pliers and I came across these for about £13.50. So I got a set with the brass inserts and a set with the normal steel jaws.

View attachment 186264

ATB

OzzyO.