Rob R

Western Thunderer

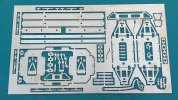

Col,I think the planks on these wagons are about 2 3/8" thick, certainly going by the LMS drawings I have, I wood imagine the GWR wagons would have been similar. So the ply would need to be 1.4mm.

Col.

No doubt someone will correct me if I am wrong but I believe you can usually only laser cut from one side, so if you want your planks marking inside and out you need to use two layers.