Hello All,

It has been far too long since my last post but here, at last, is an update.

A number of factors have conspired to limit modelling time in the past months. Chief amongst these is work but domestic projects have also impinged.

Some development work on the layout itself has continued at a glacial pace and a few repairs have been completed.

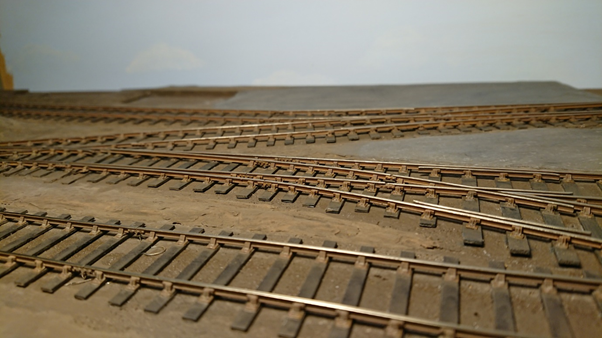

Three items needed attention to get them working correctly. The first was a broken solder joint on one of the single slip tie bars. This was easily remedied with some cleaning up of the joint area, judicious application of clamps and gauges to keep everything in place and a quick touch with a hot iron.

Long term readers may remember the system of optoelectronic detectors used on the traverser to indicate occupied storage positions to the operator. One of these ceased to function correctly. After some detective work the fault was traced back to a bad connection on one of the circuit boards. Again, a good clean and application of heat and solder fixed the problem.

The final issue was with one of the turnout operating mechanisms. The mech in question had been working fine but after a period of time, was not providing sufficient throw to move the blades completely. This particular unit operates differently from the others on the layout in that drive is provided to one end of an extended tie bar rather than to the centre point. This method of working was adopted to enable mounting of the point motor in a sensible place. With all the design work that was carried out in advance of building, I should have spotted the error. it was found that a few bits of loose material had got into the limited space around the moving parts. Once this was cleared out and a slightly thicker operating wire substituted in the Tortoise motor, everything worked well again.

Vegetation has finally made an appearance at Marchford Creek after months of avoidance. For the most part everything has gone well in this endeavour. I have used various lengths and shades of static grass together with ground foam, rubberised horsehair and scatters. The techniques used came from Gordon Gravett’s excellent book and other published sources.

A few minor bits and pieces of development work have been completed. In order to enhance the night mode lighting, connectors have been fitted to the buildings which are fitted with lights. These make it easy to disconnect the power supply when removing buildings from the layout. The units used are from the Molex kk254 series, which can be had from a number of electronics suppliers. The transfer sheds have been fitted with exterior lights sourced from Layouts-4-u. I had intended to scratch build this but struggled to form a convincing shape for the shade. In line variable resistors have been added to these installations to allow adjustment of light intensity.

The shed has also gained a drain cover at the base of the downpipe. This was formed from a Wizard Models etch.

A batch of point levers has been made up from Shire scenes etches and painted ready to fit.

My first sprung wagon is almost complete! The underframe (Rumney Models) glides silkily through my indifferent point work despite not yet being weighted to the required 50g. The body and container (Parkside) are painted and all the parts for fixing the two together are to hand. These comprise shackles, chain links and some spring units to be formed from fine brass tube. Paul Bartlett’s online wagon resource was invaluable for getting an understanding of the details for this.

Two other wagon kits are in build using different springing units for comparison. More on this will follow.

A long-planned project to make a new version of my Sprat and Winkle coupling jig has been completed. While the MK1 version (previously described in these pages) performed adequately, it was rather crude in its construction. Acquisition of my Proxxon mini mill last year meant I could construct a more sophisticated replacement. This is s useful bit of kit for consistent assembly of couplers.

My High Level Hudswell Clarke loco build has finally made it to the paint shop after many months in the drawer followed by some shenanigans with electronics. Again, some more details will follow.

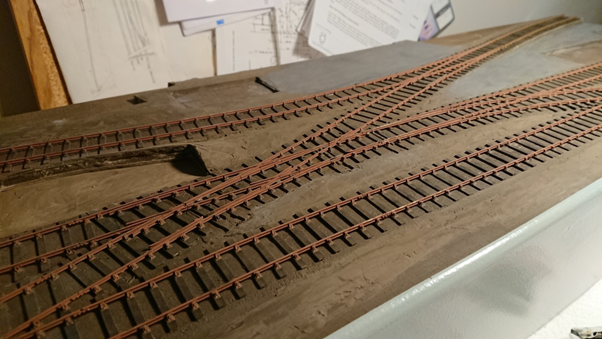

Finally, here are a few images showing the layout as it currently stands. There is still a great deal to do on scenic development but the presence of some grass and a few weeds and bushes has made a big difference.