Hello all,

the fiddle yard gang are doing well (not surprising as about 5 of them are involved now). Kev has made a start on the two curved three way points at the entrance to this end of the fiddle yard.

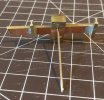

My first point for the front of the layout done apart from the details, I think that it looks ok. The track on the R/H side is not fixed down.

Then I had the fun job (not) of filing up 16 point blades. After I had finished filing the first side of 8 I thought that there must be a better way, so I sat and had a drink and a think. I came up with a plan to use the mill, the first job was to set up the jig in the vice. To do this I had to use the clock to set the part of the top face that I wanted parallel to the table. A bit of rag to clean off but a lot quicker than filling.

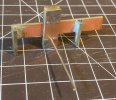

Before and after a clean up.

But you always get one naught boy in the play ground, and this was him.

After seeing the headmaster this is what he looked like.

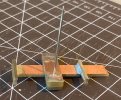

All sixteen blades done, I may have another two pairs to do. But now I've got this sorted not a big problem.

All I have to do now is to try and figure out how to M/C the flat face of the blades!

ATB

OzzyO.