Andy Ross

Active Member

Hello

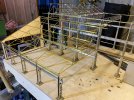

For several years I have been working on a models of Hunslet works. This includes a section of the interior of the boiler and erecting shop.

Until recently I had spent time designing and making a large number of assemblies and parts. There were some small mock ups made to see if things worked such as the cranes but it was all very slow. Just before Christmas a good friend Peter Kirmond broke off his York project and made the two baseboards.

Since then a lot of the main building has come together and I thought it may be of interest to members on this site.

The photos below were taken at York Show at Easter.

As I have progressed with the project I have embraced new technology and in the last year I have bought a 3d printer which has solved lots of issues such as making engines and transmissions for locomotives and even dummy frames for smaller locos such as the Snowdon Mountain Railway Diesl locomotives.

The photos below were taken a few weeks ago with a lot more progress on the roof structure and more recently the adding on of the wheel shop.

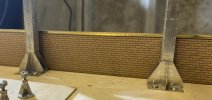

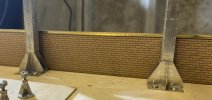

I have also purchased a small Diode laser and this is proving to be very useful.

I was not sure if t would do brickwork etc but we have done some test pieces and it works both on plywood and MDF.

Same loco below just a bit further down yard.

First go with laser on MDF for retaining wall.

If no one has any objections I will add to this as the layout develops.

Also if you would like to see it, I am taking it down to LarkRail on the 15th July.

Andy

For several years I have been working on a models of Hunslet works. This includes a section of the interior of the boiler and erecting shop.

Until recently I had spent time designing and making a large number of assemblies and parts. There were some small mock ups made to see if things worked such as the cranes but it was all very slow. Just before Christmas a good friend Peter Kirmond broke off his York project and made the two baseboards.

Since then a lot of the main building has come together and I thought it may be of interest to members on this site.

The photos below were taken at York Show at Easter.

As I have progressed with the project I have embraced new technology and in the last year I have bought a 3d printer which has solved lots of issues such as making engines and transmissions for locomotives and even dummy frames for smaller locos such as the Snowdon Mountain Railway Diesl locomotives.

The photos below were taken a few weeks ago with a lot more progress on the roof structure and more recently the adding on of the wheel shop.

I have also purchased a small Diode laser and this is proving to be very useful.

I was not sure if t would do brickwork etc but we have done some test pieces and it works both on plywood and MDF.

Same loco below just a bit further down yard.

First go with laser on MDF for retaining wall.

If no one has any objections I will add to this as the layout develops.

Also if you would like to see it, I am taking it down to LarkRail on the 15th July.

Andy