I've purchased a Mars 3pro. I was after an Elegoo special from their website but for some reason they appear to have stopped selling specials direct to the UK, so ended up with this.

I've set it up and printed the Phrozen test piece so have now got, hopefully, workable settings for my prints. First print is now going in the machine but obviously waiting to see how it looks.

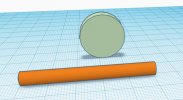

Next print I want is this station clock shown. How do I orientate it with Chitubox? If I have it standing it'll take 15 hours or more. If I lay it on its side at say 80deg will that work?

I've set it up and printed the Phrozen test piece so have now got, hopefully, workable settings for my prints. First print is now going in the machine but obviously waiting to see how it looks.

Next print I want is this station clock shown. How do I orientate it with Chitubox? If I have it standing it'll take 15 hours or more. If I lay it on its side at say 80deg will that work?