David Mylchreest

Active Member

I haven't done any modelling for years having become very discouraged and lacking in motivation to do anything really during the lockdown. Interest has been picking up however and this High Level 03 Chassis build will, fingers crossed, get me going.

I bought the kit at Scaleforum 2022 and got the wheels from Alan Gibson at the same time. It's going to be P4 and battery radio controlled when it's finished.

The first task was to read through the destructions after downloading them of course. I did have a few issues as I'm not too sure about the Fig Numbers even after reading through several times

The first task is to remove the steps and the sand boxes from the body which I acquired several years ago from Richards Spares at a show.

The second was to remove the steps component from fret and fettle it. The areas marked on black marker pen have to be removed for a model which features the recessed front steps.

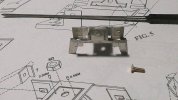

The next step is to drill the holes with a 0.5mm drill. Not all these holes are fully etched through, so I used a mini drill.

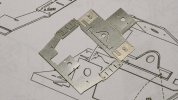

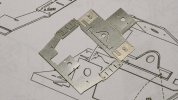

The component shown next to the instructions

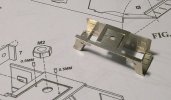

And on it's own.

I stopped there as my eyes, which don't have much depth of field nowadays, were getting tired

I bought the kit at Scaleforum 2022 and got the wheels from Alan Gibson at the same time. It's going to be P4 and battery radio controlled when it's finished.

The first task was to read through the destructions after downloading them of course. I did have a few issues as I'm not too sure about the Fig Numbers even after reading through several times

The first task is to remove the steps and the sand boxes from the body which I acquired several years ago from Richards Spares at a show.

The second was to remove the steps component from fret and fettle it. The areas marked on black marker pen have to be removed for a model which features the recessed front steps.

The next step is to drill the holes with a 0.5mm drill. Not all these holes are fully etched through, so I used a mini drill.

The component shown next to the instructions

And on it's own.

I stopped there as my eyes, which don't have much depth of field nowadays, were getting tired

Last edited:

. Then I cleaned up the surplus on the outside.

. Then I cleaned up the surplus on the outside.