You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

3d Printing

- Thread starter 28ten

- Start date

Pugsley

Western Thunderer

Shapeways seems to be the one that crops up most often. Another one that I've seen mentioned is iMaterialise, their Prime Grey material seems to have a pretty good resolution. An example of a model created in that material can be found here:

http://www.rmweb.co.uk/community/index.php?/blog/172/entry-9169-revised-middleton-bogie-sla-model/

and a bit more info here:

http://www.rmweb.co.uk/community/index.php?/blog/172/entry-9169-revised-middleton-bogie-sla-model/

I was going to give them a go for the first iteration of the parts for the twins, but depending on the final resolution of the iMateralise option, I'll probably get the actual masters done through Finelines. Expensive, but the resolution is something like 0.04mm and creates parts that need virtually nothing in the way of finishing.

http://www.rmweb.co.uk/community/index.php?/blog/172/entry-9169-revised-middleton-bogie-sla-model/

and a bit more info here:

http://www.rmweb.co.uk/community/index.php?/blog/172/entry-9169-revised-middleton-bogie-sla-model/

I was going to give them a go for the first iteration of the parts for the twins, but depending on the final resolution of the iMateralise option, I'll probably get the actual masters done through Finelines. Expensive, but the resolution is something like 0.04mm and creates parts that need virtually nothing in the way of finishing.

28ten

Guv'nor

I have seen some items done by finelines, but they could be rather pricy for what I have in mind. Imaterialise look quite promising though  . When I last used shapeways i wasnt wildly impressed, but that was 18 months ago and I know a lot can change in that time. Their plus point is the ease of uploading via a software plug in.

. When I last used shapeways i wasnt wildly impressed, but that was 18 months ago and I know a lot can change in that time. Their plus point is the ease of uploading via a software plug in.

. When I last used shapeways i wasnt wildly impressed, but that was 18 months ago and I know a lot can change in that time. Their plus point is the ease of uploading via a software plug in.

. When I last used shapeways i wasnt wildly impressed, but that was 18 months ago and I know a lot can change in that time. Their plus point is the ease of uploading via a software plug in.Pugsley

Western Thunderer

The parts I'm looking at, such as the buffers and axleboxes are only small, so the Finelines process should be perfect for those and not too expensive. I don't think I'd be getting anything too large done by them.

This wouldn't have anything to do with railbuses would it, by any chance?

This wouldn't have anything to do with railbuses would it, by any chance?

adrian

Flying Squad

I don't think that much has changed - Alan Cox has posted a few issues with Shapeways and is looking for alternativesWhen I last used shapeways i wasnt wildly impressed, but that was 18 months ago and I know a lot can change in that time. Their plus point is the ease of uploading via a software plug in.

https://plus.google.com/111104121194250082892/posts/E6iMT5xma7B

28ten

Guv'nor

PossiblyThis wouldn't have anything to do with railbuses would it, by any chance?

put it this way there is no other easy of doing that curved cab window and the resolution doesn't need to be that high for the ends as there wont be any other detail so a bit of filling wont be difficult. I have some track chairs almost ready and Finelines would be viable for that.

put it this way there is no other easy of doing that curved cab window and the resolution doesn't need to be that high for the ends as there wont be any other detail so a bit of filling wont be difficult. I have some track chairs almost ready and Finelines would be viable for that.I recently drew up some R/C rotor assemblies and they went straight into 5 axis cnc mill which was quite impressive to see in action. Not that I am a machine tool junkie in any way

Pugsley

Western Thunderer

Me neitherI recently drew up some R/C rotor assemblies and they went straight into 5 axis cnc mill which was quite impressive to see in action. Not that I am a machine tool junkie in any way

I keep looking at that kind of thing and thinking 'wouldn't it be really useful', but I don't think I could justify that level of investment without finding some serious work for it, so it could pay for itself, or at least cover some of the cost.

Dan Randall

Western Thunderer

Me neither

I keep looking at that kind of thing and thinking 'wouldn't it be really useful', but I don't think I could justify that level of investment without finding some serious work for it, so it could pay for itself, or at least cover some of the cost.

I don't know how much we're talking about here, but there's probably a lot of potential work out there from several of the members (including me), on this forum.

I was thinking it might be nice if we could all chip in for such a machine - I then realised that some poor sod would not only have to find room for it in his workshop, but would also have to learn how to use it and then spend some of his (potentially scarce), modelling time banging out stuff for the others!

Oh well, back to the 3D drawing - it's a good thing I enjoy doing it!

Regards

Dan

Simon

Flying Squad

Possiblyput it this way there is no other easy of doing that curved cab window and the resolution doesn't need to be that high for the ends as there wont be any other detail so a bit of filling wont be difficult. I have some track chairs almost ready and Finelines would be viable for that.

I recently drew up some R/C rotor assemblies and they went straight into 5 axis cnc mill which was quite impressive to see in action. Not that I am a machine tool junkie in any way

The curved cab window(s) look to me to be the "killer question" on the AC railbus.

After the 122 (ha ha ha ha) it is next on my list.

Kit-wise I would have thought it would be a real winner (I'm talking 1/32 here).

I'd happily contribute to such a project, my vague idea has been to make the body in one piece in plastikard and filler type method and get it cast by CMA, which means stumping up for 50 odd pieces. The curved glazing is what has defeated me, all the glazing would be best done (I guess) by clear cast resin pieces that fit into the apertures (Like Fred's mk 1) but without the need to paint the edges, if you see what I mean. The roof could be faitly reasily "home cast" I think to save money.

Shapeways-wise, I thought a problem was that cost went up a lot when volume (ie scale) goes up. Good for patterns though?

Alternatively send all your digital info to China and get it properly squirted - you could be the new Mr Heljan - make a fortune and enjoy lots of helpful comments from knowledgeable fellows on the Internet that have your best interests at heart

Simon

Pugsley

Western Thunderer

Not enough to cover the cost of a shiny, lovely 5 axis machine tool, I suspect!I don't know how much we're talking about here, but there's probably a lot of potential work out there from several of the members (including me), on this forum.

28ten

Guv'nor

No I dont think so. I could fancy the larger brother to Jims machine the KX3 http://www.arceurotrade.co.uk/Catal.../CNC-Milling-Machines/Sieg-KX3-CNC-Hobby-MillNot enough to cover the cost of a shiny, lovely 5 axis machine tool, I suspect!

I have also been seriously looking at CNC routers to handle the metal cutting jobs I cant do with the laser

28ten

Guv'nor

The glazing is fairly simple, the acrylic I use can be formed with a little heat.The curved cab window(s) look to me to be the "killer question" on the AC railbus.

After the 122 (ha ha ha ha) it is next on my list.

Kit-wise I would have thought it would be a real winner (I'm talking 1/32 here).

I'd happily contribute to such a project, my vague idea has been to make the body in one piece in plastikard and filler type method and get it cast by CMA, which means stumping up for 50 odd pieces. The curved glazing is what has defeated me, all the glazing would be best done (I guess) by clear cast resin pieces that fit into the apertures (Like Fred's mk 1) but without the need to paint the edges, if you see what I mean. The roof could be faitly reasily "home cast" I think to save money.

Shapeways-wise, I thought a problem was that cost went up a lot when volume (ie scale) goes up. Good for patterns though?

Alternatively send all your digital info to China and get it properly squirted - you could be the new Mr Heljan - make a fortune and enjoy lots of helpful comments from knowledgeable fellows on the Internet that have your best interests at heart

Simon

If it gets that far the plan is to use printed ends and laser the rest, which is the most cost effective solution for a one off. For a kit I would go etches and cast resin ends as the most suitable method for small batches.

Dog Star

Western Thunderer

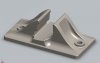

Few more fillets in, just the key and bolts to add, and looking at the screenshot I may reduce the fillet radius in a few places

I think that this comment might be true irrespective of the company.... what about:-

* company name;

* date of casting;

* rail section;

* chair type;

* place of casting (Sn for GWR... otherwise could be supplier identity).

I doubt that such could be seen in 4mm, probably not in 7mm.... interested as to the scale at which such details become (a) printable and (b) readable.

regards, Graham

28ten

Guv'nor

The lettering will be added as to the final versionI think that this comment might be true irrespective of the company.... what about:-

* company name;

* date of casting;

* rail section;

* chair type;

* place of casting (Sn for GWR... otherwise could be supplier identity).

I doubt that such could be seen in 4mm, probably not in 7mm.... interested as to the scale at which such details become (a) printable and (b) readable.

regards, Graham

A slightly bigger problem has reared its head, in that the code 180 rail wont fit a scaled chair . There is not much in it but the base sketch will need to be modified. I dont have any 7mm chairs to hand but I guess the area on the LHS between the chair and rail is filled to make a slightly more robust unit ? On the plus side I can now draw up a chair in 10 minutes

A slightly bigger problem has reared its head, in that the code 180 rail wont fit a scaled chair . There is not much in it but the base sketch will need to be modified. I dont have any 7mm chairs to hand but I guess the area on the LHS between the chair and rail is filled to make a slightly more robust unit ? On the plus side I can now draw up a chair in 10 minutes  The real test will be getting a useable resin chair out of all this, if it does work (and its a big if) then the door opens to all sorts the chairs that I dont know the names of

The real test will be getting a useable resin chair out of all this, if it does work (and its a big if) then the door opens to all sorts the chairs that I dont know the names of

Simon

Flying Squad

Few more fillets in, just the key and bolts to add, and looking at the screenshot I may reduce the fillet radius in a few places

View attachment 10623

That looks really fantastic

Notwithstanding your comment (and I've every confidence in your judgement) the radiusing of the "corners" has stopped it looking like a Lara Croft version of a real thing. What you now need (I guess) is a good tough resin in which to cast them, I don't think the "normal" stuff is quite up to it - in the mechanical strength department that is.

Very impressive work nonetheless

Simon

Simon

Flying Squad

The lettering will be added as to the final versionA slightly bigger problem has reared its head, in that the code 180 rail wont fit a scaled chair . There is not much in it but the base sketch will need to be modified. I dont have any 7mm chairs to hand but I guess the area on the LHS between the chair and rail is filled to make a slightly more robust unit ? On the plus side I can now draw up a chair in 10 minutes

The real test will be getting a useable resin chair out of all this, if it does work (and its a big if) then the door opens to all sorts the chairs that I dont know the names of

View attachment 10627

Bl**dy well done for spotting that before going any further!!

Simon