You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

MOVING COAL - A Colliery Layout in 0 Gauge

- Thread starter PhilH

- Start date

PhilH

Western Thunderer

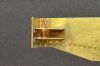

Moving on to the two pairs of scratchbuild frames, the first job was to solder the inner and outer frames together

......using a blowlamp and 70W soldering iron

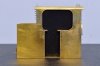

The two sections were aligned with aluminium blocks machined into a "T" shape to fit both slots

Next job will be adding all the bolts and rivets.

With the addition of the etched chassis this build has now expanded to three locos, not sure yet which the third loco will be, but it will be Giesl fitted and possibly one of the Walkden "R"s - RESPITE, REPULSE or REVENGE

......using a blowlamp and 70W soldering iron

The two sections were aligned with aluminium blocks machined into a "T" shape to fit both slots

Next job will be adding all the bolts and rivets.

PhilH

Western Thunderer

After some deliberation the favoured prototype for the third Austerity is RESPITE, which is the one I saw and photographed most often in Lancashire and Cumbria.

RESPITE was ex works from Hunslet on 26/10/1950, arriving at Walkden Yard two days later. The name is a mystery. It was one of a batch of five obtained new from Hunslet by the NCB and delivered to Walkden Yard, the other four were named after Royal Navy battleships - RODNEY, RENOWN, REPULSE and REVENGE, but as far as I know there is no RN battleship or any other RN warship named RESPITE. It remained on the Walkden System until its closure, after the last train ran on 2/10/1970, working from either Walkden Yard or Astley Green loco sheds. It was fitted with an extended bunker c1959, which was removed and a Giesl ejector and underfeed stoker fitted in Walkden Workshops during November/December 1965. RESPITE was ex works in January 1966 in red livery lined yellow, replacing the previous black lined yellow. During this conversion it was unusually fitted with a small adjustable vent in the smokebox door, presumably a Walkden experiment copying the similar vent on locomotives fitted with the Hunslet gas producer system and Kylpor exhaust, but not repeated on any other of their Giesl fitted locos. Reproducing that on the model might be a challenge.

After closure of the Walkden System RESPITE was stored at Walkden Yard until November 1972 when it made a 2 day trip by low loader up to the Ladysmith System at Whitehaven. Two years later in November 1974 it was damaged in a runaway, and then returned to Walkden Yard for repairs the same month. The repairs extended into 1975, but were completed by June when RESPITE was in steam at a works open day. Shortly after it was transferred to Bickershaw Colliery. The front part of the Giesl chimney had been patched up with a new section with square corners, the cast nameplates replaced with the name painted on flat steel plates and a new smokebox door provided without the adjustable vent. The last record I have of it working was in July 1978, on all my visits after that date it was out of use stored outside the loco shed.

RESPITE and GWYNETH were transferred to Resco Railways Ltd. in 1981 and parts from both used to construct the replica GWR 'Iron Duke' locomotive. The replica incorporated the boiler, cylinders and motion of GWYNETH, but only minor parts were used from RESPITE which remained largely intact. It was later sold for private preservation and is currently undergoing long term restoration at the Ribble Steam Railway in Preston.

RESPITE was ex works from Hunslet on 26/10/1950, arriving at Walkden Yard two days later. The name is a mystery. It was one of a batch of five obtained new from Hunslet by the NCB and delivered to Walkden Yard, the other four were named after Royal Navy battleships - RODNEY, RENOWN, REPULSE and REVENGE, but as far as I know there is no RN battleship or any other RN warship named RESPITE. It remained on the Walkden System until its closure, after the last train ran on 2/10/1970, working from either Walkden Yard or Astley Green loco sheds. It was fitted with an extended bunker c1959, which was removed and a Giesl ejector and underfeed stoker fitted in Walkden Workshops during November/December 1965. RESPITE was ex works in January 1966 in red livery lined yellow, replacing the previous black lined yellow. During this conversion it was unusually fitted with a small adjustable vent in the smokebox door, presumably a Walkden experiment copying the similar vent on locomotives fitted with the Hunslet gas producer system and Kylpor exhaust, but not repeated on any other of their Giesl fitted locos. Reproducing that on the model might be a challenge.

After closure of the Walkden System RESPITE was stored at Walkden Yard until November 1972 when it made a 2 day trip by low loader up to the Ladysmith System at Whitehaven. Two years later in November 1974 it was damaged in a runaway, and then returned to Walkden Yard for repairs the same month. The repairs extended into 1975, but were completed by June when RESPITE was in steam at a works open day. Shortly after it was transferred to Bickershaw Colliery. The front part of the Giesl chimney had been patched up with a new section with square corners, the cast nameplates replaced with the name painted on flat steel plates and a new smokebox door provided without the adjustable vent. The last record I have of it working was in July 1978, on all my visits after that date it was out of use stored outside the loco shed.

RESPITE and GWYNETH at Bickershaw in June 1977

RESPITE and GWYNETH were transferred to Resco Railways Ltd. in 1981 and parts from both used to construct the replica GWR 'Iron Duke' locomotive. The replica incorporated the boiler, cylinders and motion of GWYNETH, but only minor parts were used from RESPITE which remained largely intact. It was later sold for private preservation and is currently undergoing long term restoration at the Ribble Steam Railway in Preston.

Last edited:

adrian

Flying Squad

Undoubtedly - Yes.Did I really need 3 of these locos ?

Jordan

Mid-Western Thunderer

Did I really need 3 of these locos ?

Agreed. There is No Such Thing as "too many locos". Especially if they're a particular favourite, as well.Undoubtedly - Yes.

PhilH

Western Thunderer

Comparison of etched (top) and scratchbuild chassis. In retrospect I would have used the brass Slaters hornblocks on the scratchbuild frames had they been available when I started this project

The triangular gussets between frames and buffer beams have been carried through from side to side and located in slots in the frame ends to ease assembly. In the etched chassis I've ignored the corner cut out for the 6" angle between frame and buffer beam and taken the gusset straight through along the back of the buffer beam, as the intended recipient for the final version of the etch didn't want to do the riveted angles and flanges in the corners. I've incorporated these in my test assembly by splitting the angles above and below the gusset. I don't think the lack of a triangular gap in the corner of the gussets will be too obvious in the finished loco.

Moving back along the chassis between the frames, first is an angled plate representing the back of the cylinders, then the motion plate and a 3 part cross member just in front of the firebox. Dummy top slidebars and valve rods may be added later as a separate unit, and holes for fixing this have been provided in the cylinder and motion plates.

The bolts on the buffer beam are as on the prototype, so don't line up with the narrower frames on the model.

The riveted angles and flanges were added after the frames were assembled, so not really practical to use pins. Rivets or bolts were formed by half etching or a rivet press, and the parts fitted with an RSU. Some tidying up of solder joints is required, and the chassis will be grit blasted in due course.

Ironstone2306

New Member

Watching with interest PGH, inspiring stuff.

Paul A.

Paul A.

My first recorded visit to an industrial railway system was in August 1958 to Penrhyn Slate Quarry in North Wales. In the late 1950's to early 1960's much of the school holidays were spent with a like minded school friend exploring the railways of North Wales, travelling on many of the BR lines closed by Beeching, visiting quarries still using narrow gauge railways or walking long abandoned quarry tramways. On a visit to Port Penrhyn we were told that a school party would be travelling up the railway to the quarry later that day and we could travel with them. This was long before I started making proper notes or taking photographs, and only recorded because at the quarry we were taken through the mills on Red Lion Level to see the production of slates and were each given a slate as a souvenir on which I scratched the date of the visit.

So began a lifetime interest in industrial railways.

As the use of narrow gauge railways in the North Wales slate quarries declined in the 1960s interest widened to standard gauge systems, particularly those of the National Coal Board which were easy to access, included many lengthy systems serving several collieries and with plenty of steam power. In the next 20 years or so I made over 400 visits to various collieries, many being repeat visits to the same systems, until the last use of steam at Bold Colliery in the early 1980s.

On a typical 3 or 4 day trip to collieries in Scotland and the North of England I would have travelled up overnight with the first call being the loco shed at Waterside, Dalmellington, to find 3 locos being prepared for the days work. The first train would then be followed to the end of the line at Pennyvenie Colliery, where I could conveniently park alongside the line to photograph the arrival of Giesl fitted Andrew Barclay 0-6-0T No.24 with 17 empty NCB wooden internal user wagons for coal destined for the Waterside Coal Preparation Plant and 10 empty BR steel mineral wagons for larger sized coal to be despatched direct to BR. Coal was screened at the colliery into various sizes and dirt removed but much of the output went to the Waterside Plant for further treatment.

No.24 back at Waterside, the wagons in the background are on the line leading to the coal preparation plant wagon tipplers. The locos here ran coupled to an open wagon with the end door removed as a 'tender'. This is perhaps the opposite of what some might imagine as a typical industrial system - a filthy locomotive working in a grimy industrial location.

My own interest is primarily the Lancashire Coalfield, which probably had more variety of locomotives than any other colliery area, including three unique and individual designs built by the colliery owners and also the only three industrial 0-8-0Ts in the UK. In the NCB period the longest systems were at Standish, to the north west of Wigan, where a coal washery adjacent to the West Coast main line served two deep pits and two drift mines; Haydock, where a coal preparation plant served four collieries; and probably the most well known and extensive system, Walkden Railways, the main inspiration for the layout.

The colliery loco shed - based on the prototype shed at Walkden Yard reduced in length by a half to fit in a corner of the layout.

The layout represents a section of NCB line from a colliery, where the coal is loaded, to a coal preparation plant or washery, where the coal is unloaded for further treatment. En route the line passes a canal tip where coal will be also be discharged (theoretically into off scene canal barges). So within the layout there are three potential complete traffic movements - colliery to washery, colliery to canal tip and washery to canal tip.

I'm not sure where to go with this, most members seem to have already seen it on RMweb so there is little point in repeating all that information here.

For anybody that hasn't, the operation may be summarised in these three videos:-

PhilH

Western Thunderer

Greatly enjoyed your project and wondered if you have drawings of the tippler or can tell me where to find such. How you built yours would help me! I am building a granite quarry (at Dalbeattie) in Scale 7. Well done, Andy

Hi Andy,

A description of the building of the side tippler is here:-

MOVING COAL - A Colliery Layout in 0 Gauge

A description of the end tippler including a drawing of the tippler platform starts lower down on that same page and continues here:-

MOVING COAL - A Colliery Layout in 0 Gauge

Details of the end tippler were obtained by measuring the prototype.

PhilH

Last edited:

PhilH

Western Thunderer

Continuing with the Austerity build, there's been no progress on the actual models since the last report as I've been working on the drawing for the cab and footplate etch. This has now been completed and the first test sheet obtained from the etchers.

Half etched "hollows" have been provided on the rear or underside of each item for all the bolt and rivet detail, giving the option of punching bolts and rivets with a rivet press or drilling out for pins, This is the underside of the footplate. The half etched rectangle is to locate the steps.

Rear of cab side. I'm not sure how the sharp curve at the top will come out with the half etched strips, may need a rethink there. The line of rivets on each side of the lower cab opening were for a reinforcing angle inside, which was only provided on the last few Austerities built by Hunslet.

The next job is to see how (and if !) this all works out.

Coupling rods have been laser cut from 2mm thick mild steel, they now just require machining on their front and rear faces.

PhilH

Western Thunderer

Filing pin heads to shape to represent bolts or rivets can be time consuming but it does make the assembly of items like these steps with respective holes in the different parts a doddle.

Firebox washout plugs or mudhole doors were provided in the openings on each side of the frames. These were made by turning a brass rod to the diameter of the centre, making a saw cut across the diameter and soldering a brass strip across, which was then filed into shape. The end was faced off in the lathe and drilled for the centre fixing bolt (a pin with its head filed to shape) and the part then cut off the end of the rod.

Rather than provide the angle between the top of the rear buffer beam and the underside of the bunker I extended the footplate to form the top (horizontal) part of the angle and added a strip to the top of the bufferbeam to represent the vertical part. This latter part was drilled with holes for the rivets and bolts with the intention of drilling through the buffer beam once the strip was soldered in position. This proved to be rather a crack-brained idea as it ignored the items already fixed to the rear of the bufferbeam like frames and footplate valance, plus how the heck would I get to the rear of the buffer beam to solder and trim the pins with the footplate in position. Breaking half a dozen 0.45mm dia drills while attempting this somewhat reinforced that view. So the original strip was removed and replaced with a new strip with the rivets and bolts already fixed to it. Despite there only being 0.4mm (the thickness of the strip) length of pin fixed in the strip surprisingly I didn't lose any of the bolts or rivets in this process. A more sensible alternative would have been to form the rivets on the strip with a rivet press, although there is a small bolt head at each end of the row. Just in case you're wondering there are 3 different sizes of rivet head in the row. The black areas round some of the rivets are traces of solder which has leaked out from the rear. Cleaning with Cif seems to turn this solder black.

tbc

PhilH

Western Thunderer

The brackets on the cab front will retain the back of the 3D printed tank/boiler unit, which then just requires a bolt between the smokebox and the footplate to retain the unit in position. On the prototype these brackets would be welded to the tank and bolted to the cab front. The cab floor was elevated slightly with a slip of paper underneath when the sides and front were soldered in position to ensure that the sides and front fit tightly to the footplate when the cab floor is bolted to the footplate.

Some of the Walkden Austerities were fitted with cab doors, and these were stepped back from the cab sides to clear the vertical handrails with steel angles attached inside the cab on each side of the doorway. Only the last 4 locos delivered new by Hunslet to Walkden Yard had these angles fitted by rivets, this includes the 2 prototype locos represented here. The rivets are quite small and were formed from short lengths of 0.4mm dia wire soldered in pre-drilled holes, trimmed to length and then rounded off with steel wool. The bunker top edge will be provided with half round beading.

The bars over the rear windows are 1/2" dia in the prototype, near enough 0.3mm to scale. I thought these would be a bit delicate so used 0.4mm dia. wire. However this does look a bit heavy, but might be a bit less noticeable when they're painted black. Next time I'll do them in 0.3mm dia. The small door between the windows was for access to the top lamp iron, which was fixed to the bottom right hand corner of the door. Some locos had the lamp iron in place, others didn't - as the prototype represented here.

The bunker front inside the cab. This should have been fitted before the cab rear as I subsequently found out. Its since been fitted in place but I had to separate the top from the vertical part to get it in.

tbc

john lewsey

Western Thunderer

Nice work Phil a working railway .when I was about fifteen I used to go to Croydon B Power station they had saddle tanks .i managed to get an afternoon on the footplate absolutely fascinating

John

John