You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Roxey models 0 gauge Austerity

- Thread starter sagaguy

- Start date

Richard Gawler

Western Thunderer

Progress on the WD tender,only one spring pinged into the black hole of the carpet,now onto the brakes.

Each time I drop something and go to search on my carpet I find a part I dropped some time ago. Even 14BA nuts and the tiniest of springs have turned up this way.

Eastsidepilot

Western Thunderer

Walk around with bare feet, you'll soon find 'em !

Col.

Col.

Yorkshire Dave

Western Thunderer

When things drop in to the carpet monster I sweep a magnet across a large swathe of the floor as items have a habit of bouncing. This picks up all magnetic items... screws, springs, etc....

.....and other rubbish as well.

.....and other rubbish as well.

Richard Gawler

Western Thunderer

I suppose the feet will catch the non-ferrous items as well. I will give them a try.

Focalplane

Western Thunderer

I don't recommend the bare foot technique. My big toe found the very sharp end of a broken mini hacksaw blade. Blood everywhere and the piece acted like a fish hook, it would not come out! Eventually all was fixed but plenty of blood stains on the Railway Room carpet to remind me of my folly.

simond

Western Thunderer

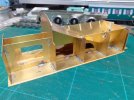

A roundup of work so far on the tender.Why is it that no matter how I hold parts in alignment, they are always out of alignment after soldering, ie,the tender side sheet

I’d hazard a guess: you got the side sheet hotter than the footplate (with all the other structural bits already attached, so big thermal mass) when soldering them together, and when the assembly cooled, the side sheet contracted more than the footplate. Footplate ends up curved, and can only move one way because the side sheet stops it going t’other.

Rather than flood with solder, which will leave you with a dished footplate, and one or both ends of the side plate marginally in the wrong place, you can remove it and try again, but start by tacking the middle, or unsolder one end, let it cool, then resolder. Lots of flux, clean job & solder, hot iron, minimal solder on iron, and in-out quick.

or, if you’re brave, take the body off the chassis, lay it on a tile or firebrick, ensure the side plate can’t fall over, and a very quick blast with a blowlamp will run the solder the length of the job very neatly.

Richard Gawler

Western Thunderer

A bit of a long shot but you might unsolder the floor, clean up and leave it unsoldered. Attach some scrap shim around the top of the floor to centre it on the body. Secure the body, floor and chassis together as a sandwich and you will get an accessible space inside the model able to hold a decoder or speaker in the future.

Pencarrow

Western Thunderer

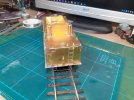

I'm really not in the same league as others on this forum when it comes to soldering but... I've got a lot of mistakes under my belt.It`s really just a gap filling exercise,it could be done with filler but i like solder for this job.To be honest,the construction of this tender wouldn`t allow it to be taken apart.It won`t dish,the formers inside are firmly soldered to the floor.View attachment 178222

On this basis, and looking at the last photo, dare I suggest that the soldering iron may need a few more watts? The solder doesn't seem to be flowing so I'm guessing the iron is struggling to heat the joint quickly and therefore you're dwelling a while and pumping heat into the wider brass. This might result in the uneven heating and cooling Simon suggested.

I am however not really qualified to offer opinion on soldering but I did find a higher wattage iron helped me on bigger 7mm stuff. Napalm has also been considered on one loco...

Heat isn`t a problem,i use an Atten ST-100 soldering station which is a 100w unit.I use Carrs 145 solder running the iron at 430 degrees so i have no problem soldering seams,this pic shows the side just tacked to make sure that it doesn`t move when i return to it tomorrow or Saturday.I'm really not in the same league as others on this forum when it comes to soldering but... I've got a lot of mistakes under my belt.

On this basis, and looking at the last photo, dare I suggest that the soldering iron may need a few more watts? The solder doesn't seem to be flowing so I'm guessing the iron is struggling to heat the joint quickly and therefore you're dwelling a while and pumping heat into the wider brass. This might result in the uneven heating and cooling Simon suggested.

I am however not really qualified to offer opinion on soldering but I did find a higher wattage iron helped me on bigger 7mm stuff. Napalm has also been considered on one loco...

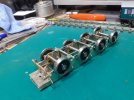

Still busy ,for some reason,although i`m retired,i don`y know how i found the time to go to work.However,one side fitted with axle boxes,spring hangers and equalisising beams etc.I hadto epoxy these parts,my 100w iron couldn`t handle the acres of brass.Plenty of castings to fettle and fit,now onto the other side.

Ray

Ray

Clarence3815

Western Thunderer

Has anyone built the JLTRT WD tender and can compare it with this one please?

Ian@StEnochs

Western Thunderer

Clarence3815

Western Thunderer

Very many thanks.

Bernard

Bernard

I thought about this kit when i first started looking for a WD kit but when i went to put my order in,the kits went off the market.I do have a soft spot for WD Austerities,this my part built 5" model.View attachment 185456

Yes, this is mine but.its currently being painted and I am away from home until Friday. I will post anither view when I get home.

Ian.

Ray.