Having purchased a Connoisseur Models J71 kit I realised the frames as they come are too narrow for S7. Too wden the frames I needede a way of hodling them whilst fitting the wider frame spacers.

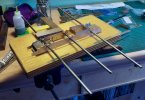

I have turned up a couple of jigs too ho;d the frames and at the same time turned up some axle jigs to set the hornblocks accurately to yje coupling rods.

I have turned up a couple of jigs too ho;d the frames and at the same time turned up some axle jigs to set the hornblocks accurately to yje coupling rods.

Last edited by a moderator: